STUDY CASES FOR GRINDING, SANDING AND LINISHING

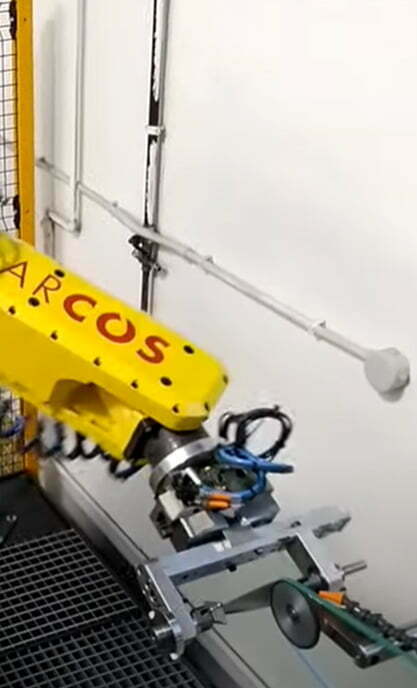

ROBOTIC SYSTEM FOR THE GRINDING OF TAPS

This robotic system is designed to automate the tap grinding process. It has great elasticity thanks to the two triple grinder units and the pliers designed to reproduce all human movements.

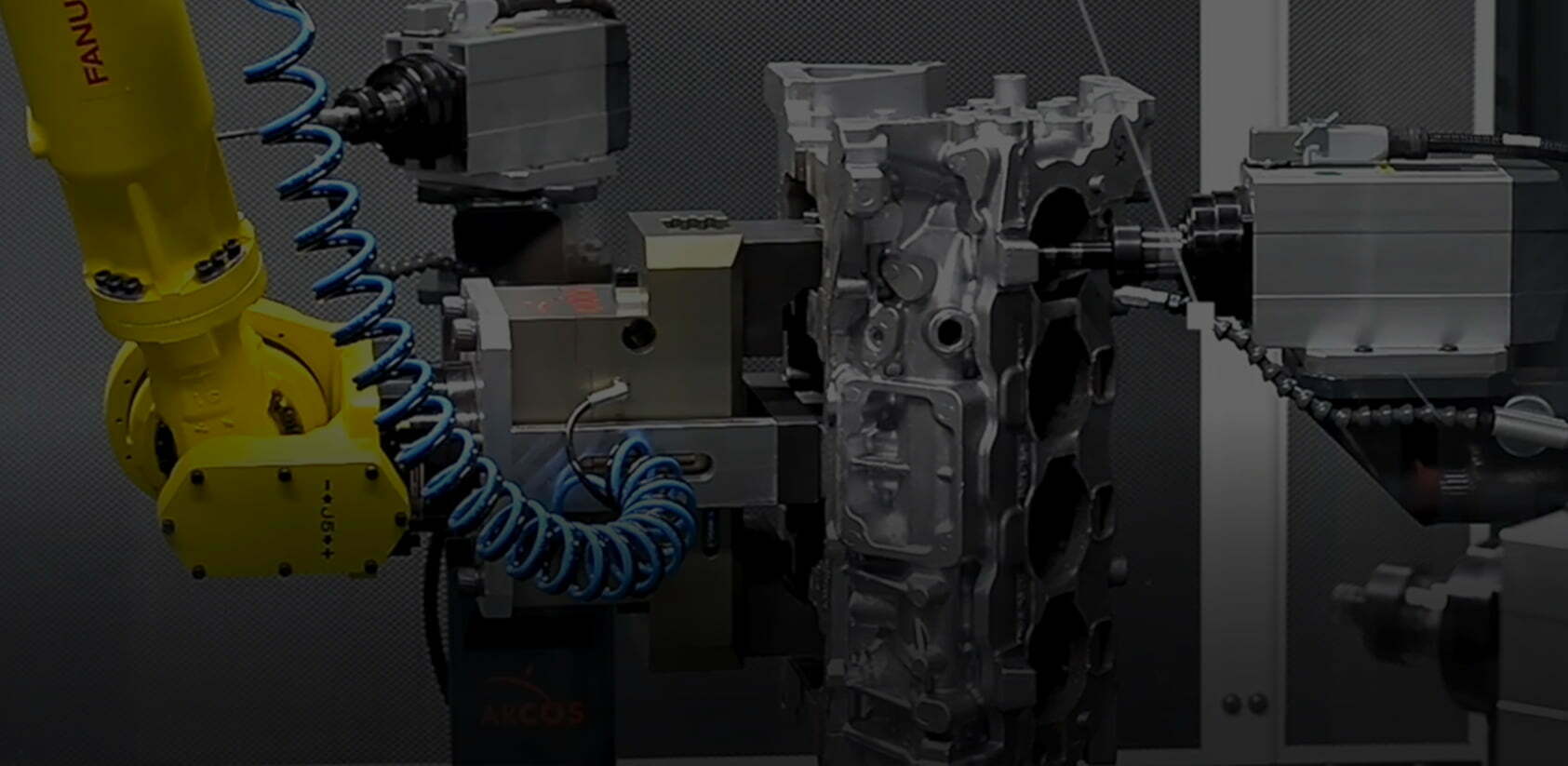

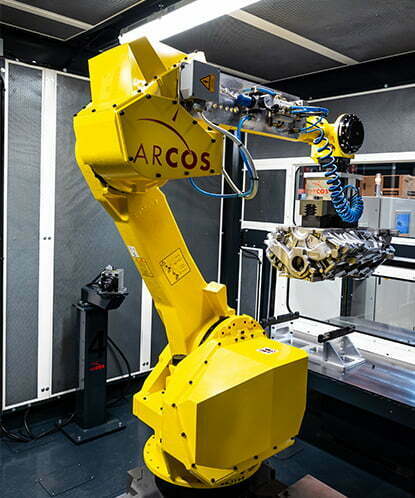

Robotic system for grinding metal components for loading systems guides

The robotic system is designed to ensure the grinding of metal components for of load system guides. The robot guarantees the right versatility to work pieces of different sizes and lengths.

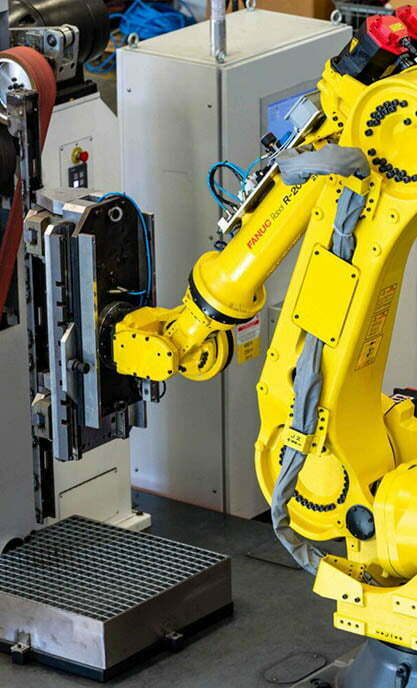

Robotic system for grinding and finishing of aluminum parts for the aerospace sector

The Robotized System allows the automatic grinding and finishing of aluminum parts in post-processing, starting from rough blades for aerospace turbines that have different twists.

- 2 SM9 units, pendulum type unit for double brush grinding;

- 3 SB3 units, spindle unit for abrasive rubber wheels;

- 1 SM6 unit, pendular unit for abrasive belt grinding;

- 1 FANUC 50 KG robot;

- 4 automatic grippers for piece locking;

- 4 claw kit for hooking each piece;

- 1 loading / unloading system by means of a rotating table;

- 1 electrical cabinet with control panel;

- Fully enclosed protection cabin.

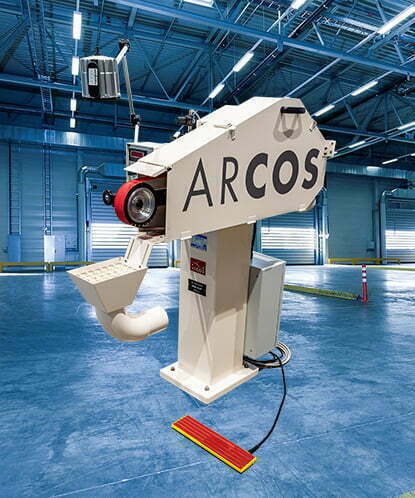

GRINDING, SANDING, LINISHING AND BELTING

TYPEs OF PROCESSING

type of materials

cast iron

glass

aluminum alloys

Steel/stainless steel

brass

zamak

hard stones

titanium alloys

Inconel ®

magnesium alloys

composite materials

plastic

Type of OBJECTS

Recommended machines for GRINDING/SANDING/LINISHING/BELTING

ROBOTISED SYSTEMS

CONTINUOUS ROTARY TABLES

INDEXED-CNC ROTARY TABLES

MANUAL MACHINES

CENTERLESS MACHINES