Many metalworking operations involve flaws that need to be removed in order to make the object clean and perfect for its intended use. These imperfections are referred to as burrs and can be removed very efficiently using robotic deburring.

Let’s go into detail about this mechanism, to understand how it works, why it is carried out and how it is applied according to the type of need in a specific field.

Table of Contents

What is deburring?

Deburring is the process of applying a surface finish to metals by removing and cleaning the burrs formed by previous processes (such as: casting, cutting, stamping, chip removal, drawing, forging, pressing, additive manufacturing). These burrs are mainly residues of material deposited in the object, which would affect the intended function of the manufact.

This is why deburring is applied using systems that guarantee unrivalled precision and speed. This phase is carried out in preparation for the grinding and polishing processes, so that all machining operations can be carried out at their best performance.

Why is deburring necessary?

Two main ways of deburring can be distinguished.

The first application is aesthetic deburring and is applied in all those parts that need to maintain a high standard of quality, especially at an aesthetic level, rather than at a functional level. This surface finish is typical of the furniture, fashion and luxury, and accessories area.

The second deburring is the precision one: burrs are removed from components that have specific application functions. In this case, the process and the tools involved must be considered in more detail, precisely because the destination of the tools is extremely demanding. In particular, in the Automotive and Aeronautics and Aerospace destinations, it is essential to avoid inaccuracies.

Deburring tools and methods

As with many other processes, deburring can be applied manually or by means of robotic systems.

This technique can be performed with two machines that Arcos has perfected over the years: robotic cells and manual machines. The reliability and flexibility of the cells make it possible to optimise the process by considerably reducing cycle times and safeguarding the operator’s health. Manual machines, on the other hand, are of great value in situations where a particular degree of finishing is required and when lots are very small.

Arcos offers innovative automatic systems for robotic deburring, capable of adapting to the geometry of the workpiece and responding to the type of result required. Deburring can be applied:

- with abrasive belts: the abrasive force of the element is exploited in the vicinity of the burr.

- With brushes or abrasive discs: these are used when the geometry of the workpiece or the fragility of the burr are constraints to the deburring process.

- With precision tools: in this case several tools may be required, depending on the extremely precise deburring step required. The carbide tools are mounted on electric or pneumatic rotating spindles and are changed as required thanks to the automatic magazine of the robotic system.

The removal of burrs can be carried out on a wide variety of materials, from cast iron, glass and steel to plastics, hard stones, titanium alloys and many more.

Some examples of Arcos applications

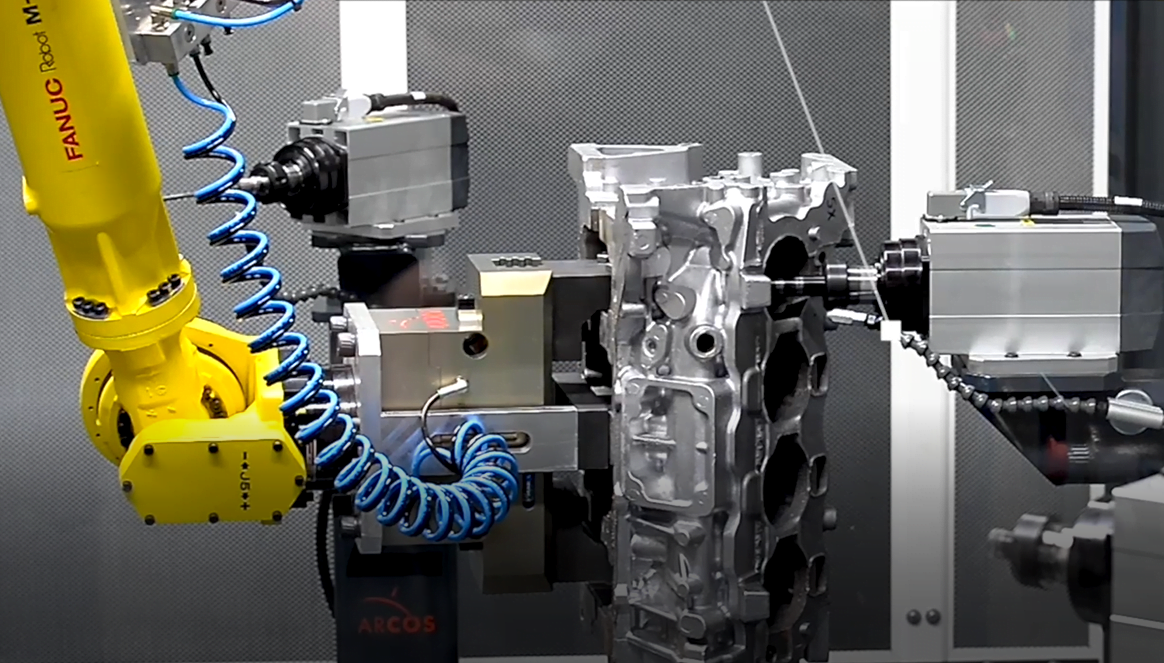

Automotive and aerospace are some of the main fields where a strong component of the deburring operation is found. Let’s take a look at two different application examples carried out using Arcos robotic systems:

- Precision deburring of supercar engine blocks.

The process is applied here on V8 engine blocks of luxury supercars within a robotic cell. Tools mounted on electro spindles make it possible to machine even those areas where access is most restricted.

- Aerospace: precision deburring of turbine blades.

Conclusion

A deburring station is now part of every production process. This stage removes imperfections caused by material residues. In particular, robotic deburring is a great advantage for the completion of this operation because the part is cleaned in a short time, with extreme precision and in a fully automatic manner.

Arcos not only offers advanced robotic systems, but also guarantees support before, during, and after installation, both on-site and remotely for lasting, precise professional support.

Need more information on robotic deburring? Contact us: our team will be at your disposal.