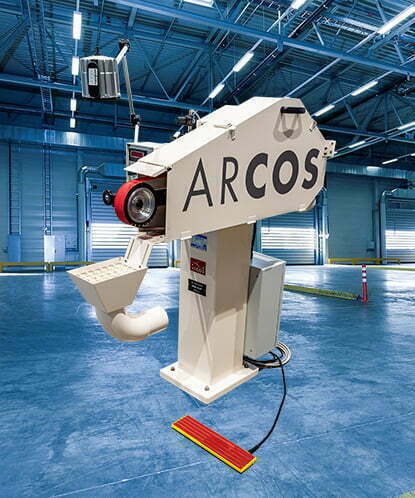

Robots for automated sanding applications

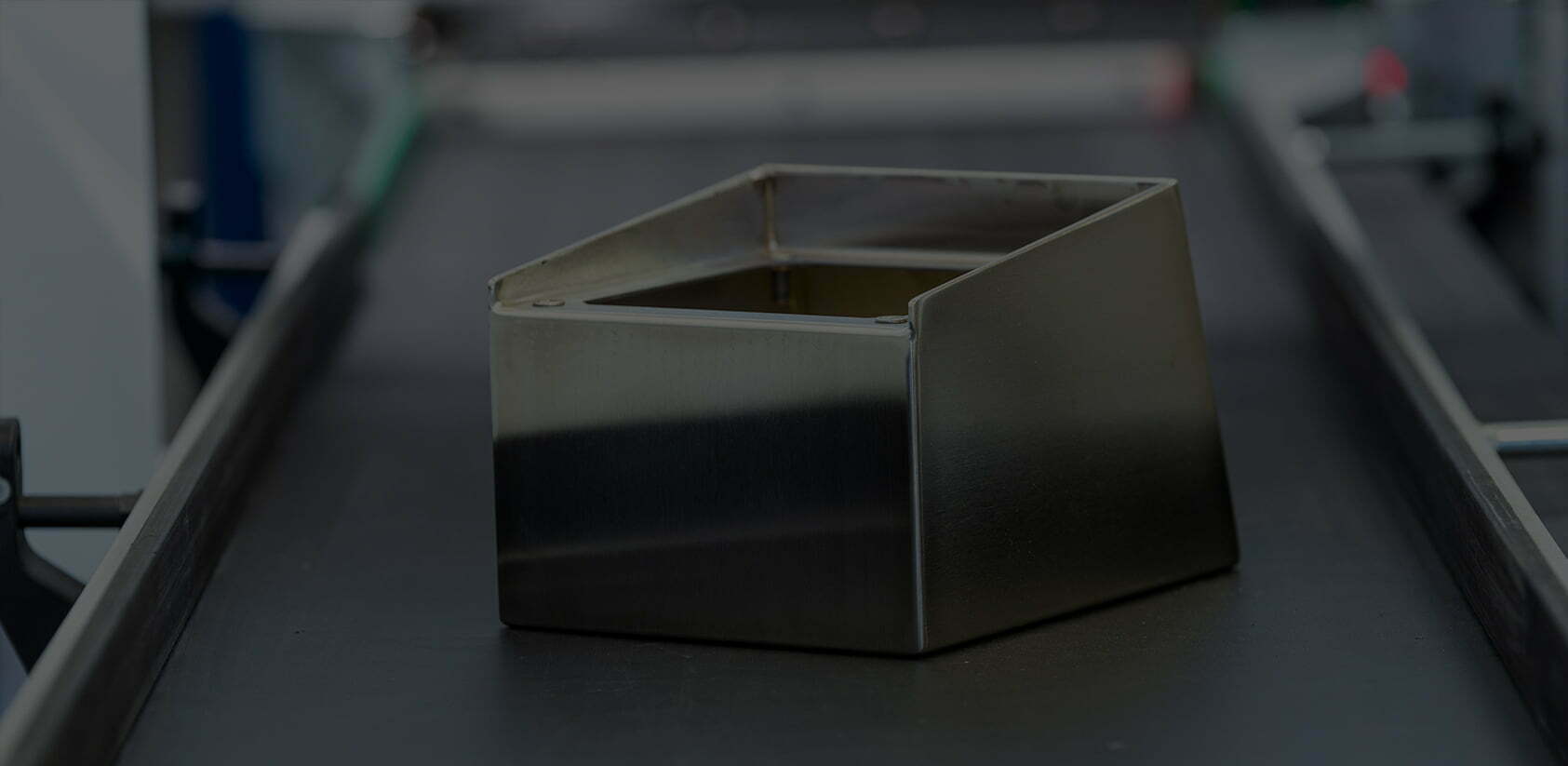

Flawless and uniform surface finish

Cut cycle times and enhance productivity

Study cases for sanding

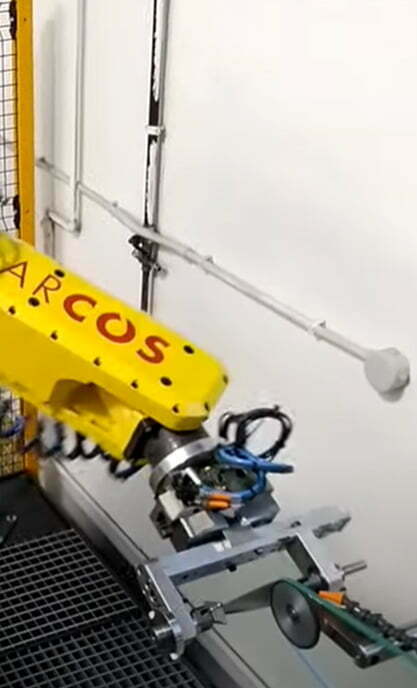

ROBOTIC SYSTEM FOR THE GRINDING OF TAPS

This robotic system is designed to automate the tap grinding process. It has great elasticity thanks to the two triple grinder units and the pliers designed to reproduce all human movements.

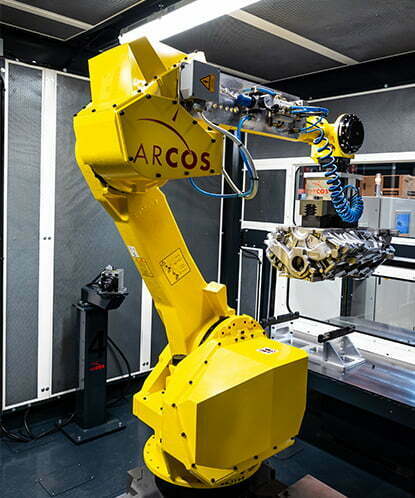

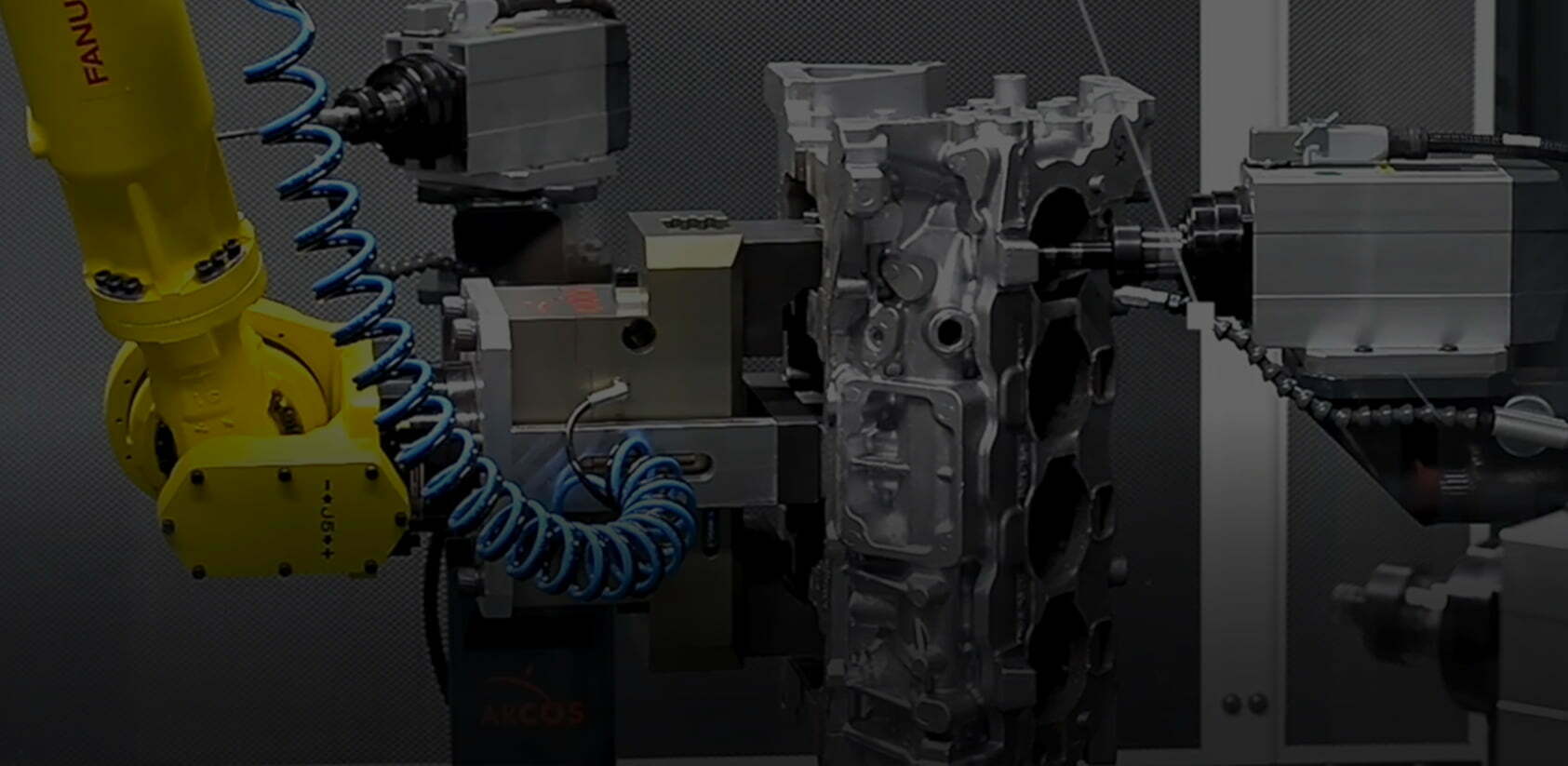

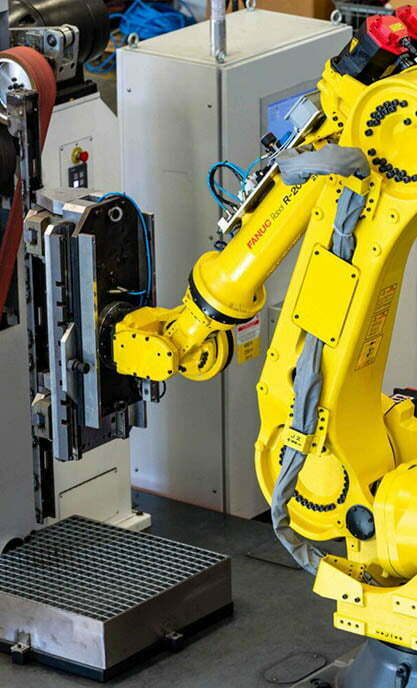

Robotic system for grinding metal components for loading systems guides

The robotic system is designed to ensure the grinding of metal components for of load system guides. The robot guarantees the right versatility to work pieces of different sizes and lengths.

Recommended machines for sanding

type of materials

cast iron

glass

aluminum alloys

Steel/stainless steel

brass

zamak

hard stones

titanium alloys

Inconel ®

magnesium alloys

composite materials

plastic