Industrial sandblasting robots

Consistent quality and precision

ROI Improvement

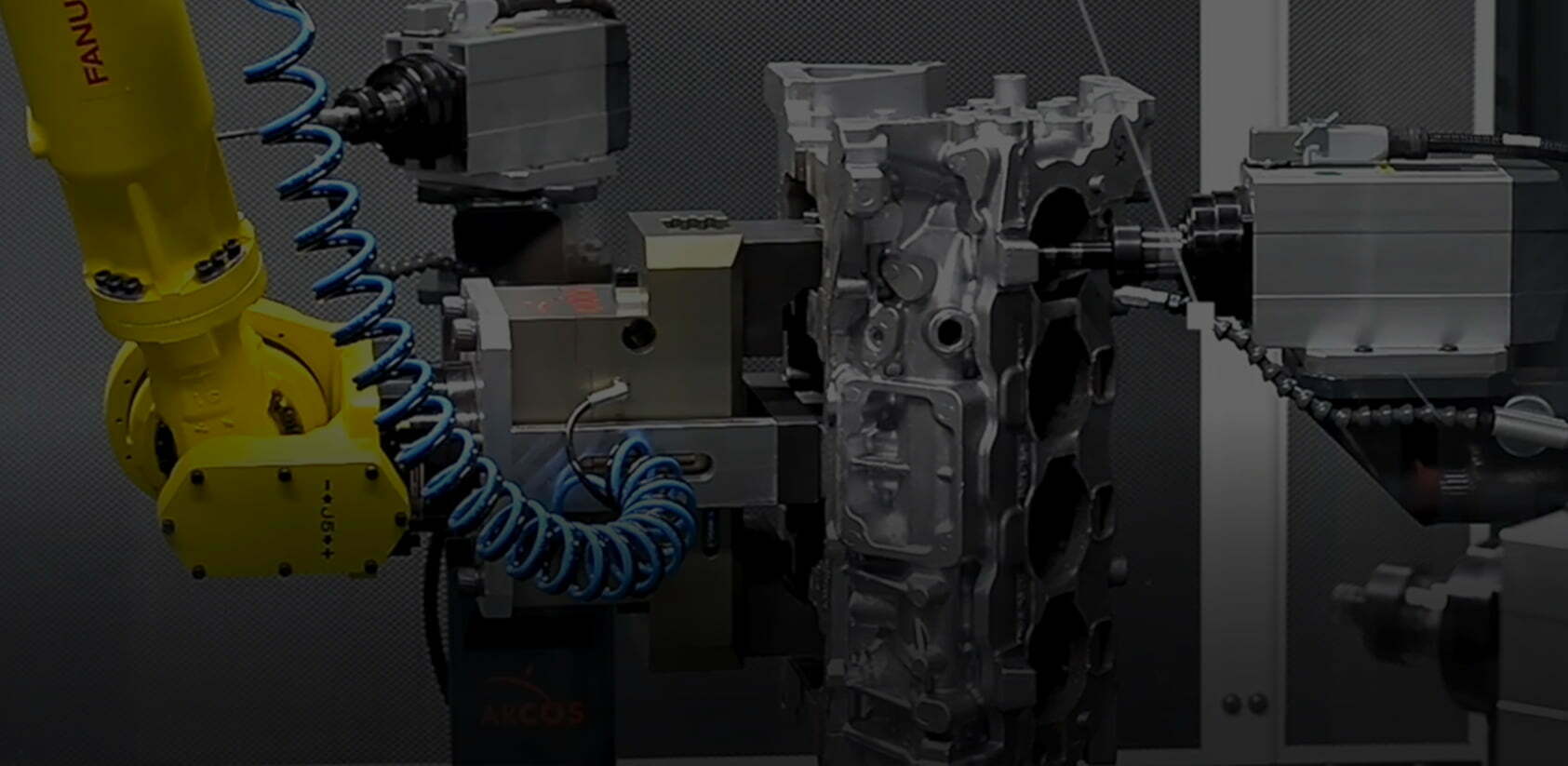

ROBOTIC SANDBLASTING

CASE STUDY FOR ROBOTIC SANDBLASTING

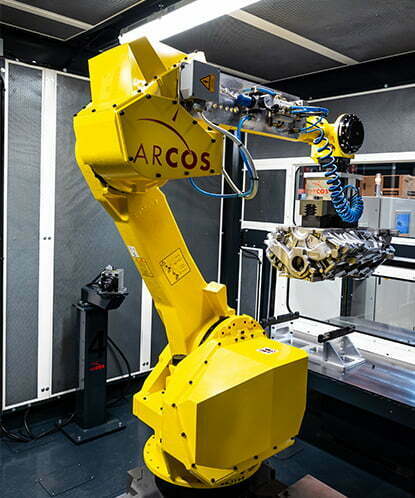

Robotic system for sandblasting of aeronautical details

The robotics system allows the automatic sandblasting of aeronautical details.

- 1 six-asses FANUC M70Ic/70 robot with DCS Fanuc safety option;

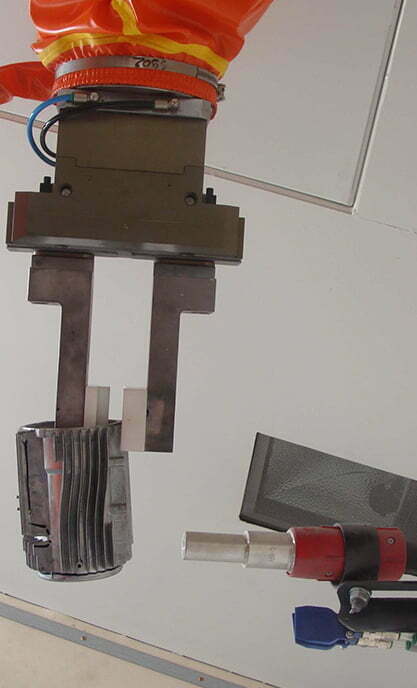

- 1 clamp for clamping work piece;

- Fanuc robot cover specially tailored;

- Loading/unloading system with drawers;

- 1 sandblasting unit for dust deposit on the work piece;

- 1 electric cabinet with HMI Proface control panel;

- Sandblasting system with filters;

- Profinet communication;

- 1 fully enclosed protection cabin.

Pieces: Details for aeronautics

Material: Aluminum

Operation: Sandblasting

RECOMMENDED MACHINES FOR ROBOTIC SANDBLASTING

ROBOTISED SYSTEMS

Materials

cast iron

glass

aluminum alloys

Steel/stainless steel

brass

Zamak

hard stones

titanium alloys

Inconel ®

magnesium alloys

composite materials

Plastic