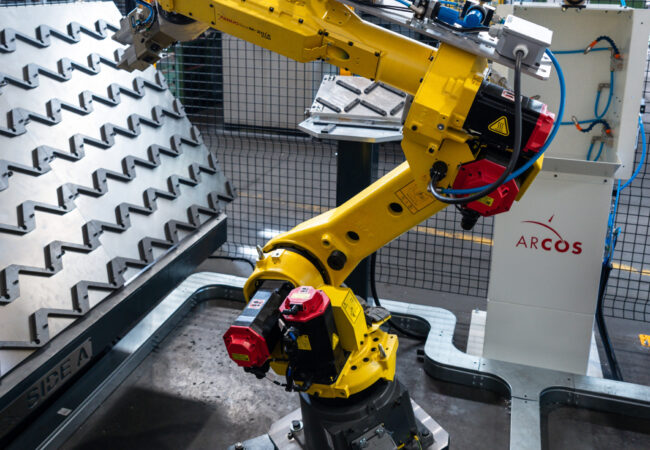

The expertise developed over the years and the sharp increase in demand for automation in a wide variety of sectors, has prompted Arcos to expand its core business to include another area of automation: robotic handling. This automated handling allows to obtain not only an increase in productivity, but also a greater well-being for the staff.

Through the centres’ machine tending, in fact, robots can speed up the process of inserting and picking up workpieces without the need for continuous monitoring or supervision: after loading the tables, the operator is free to devote himself to other activities, while the robot can continue handling even during non-working hours.

In this article, Arcos explains how production can be optimised thanks to the robotic handling of working centres.

Table of Contents

Production mechanisms and personnel: evolution over time

The evolution of the human figure within the mechanisms of production has seen a continuous and improving transition to support greater security and serenity in the performance of their work tasks.

If originally man had a direct effect on the realisation of the product through manual operations and interventions, often tiring and damaging to his health, over time the function of the human component has become one of support and back-up for the new and sophisticated numerically controlled machining centres. It has been possible to exclude human intervention in the production process thanks to the introduction of robots, which have finally allowed true autonomy to the system.

With machine tending, the main task of the personnel is to equip the loading systems, such as turntables, tray towers, conveyor belts, bins, pallets and more, so that the system has enough autonomy to work every day of the week, at any time of day.

Robots for the physical and mental health of your staff

Robotic handling to work centres therefore allows staff to play a less alienating and frustrating role, but one that is more specialised and richer in skills.

The human figure can now devote itself to supervising the cell and programming its components, totally abandoning the repetitive and extremely monotonous work that can cause depression and discontent.

This is possible mainly through two functionalities:

- By equipping the robot cells with lungs that make the process as independent as possible.

- Using quality control stations that exclude personnel from the risk of injury due to the handling of heavy parts.

The robotic handling to the work centers is not, therefore, a representation of a small part of automation, but rather a real philosophy of empowering employees. Arcos is aware of this, which is why every day it studies new machine tending mechanisms to meet customer requirements.

Every customer deserves a tailor-made solution

Usually, an Arcos robotic handling system is not just about supporting the work centre but is aimed at achieving specific objectives set by the customer.

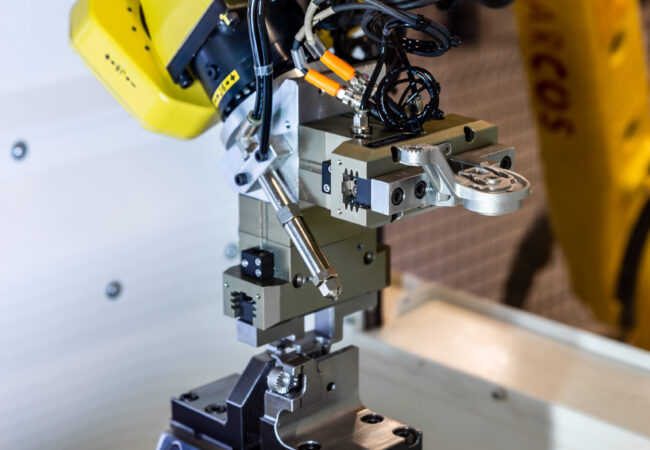

At the heart of the system is always the desire to respect the cycle time imposed by the machining centre while, in the meantime, the robots must perform in masked time the operations of quality control, palletising, tool changing and any other activity that can save time and money.

These advantages unequivocally justify the initial investment in robots, which should in no way represent the bottleneck of production systems but, on the contrary, provide flexibility, autonomy, safety, and quality to production processes.

Conclusion

The machine tending in which Arcos successfully operates are various: from the most common and traditional CNC machines to cutting, threading, and tapping stations and the handling of hot liquids in foundries.

The investment in automatic technology guarantees an advantage not only for the company, which optimizes times and significantly increases production, but also for the staff who can invest their energies in safer and more dynamic tasks, obtaining enormous psychophysical well-being.

For years Arcos has been engaged in the study and improvement of the solutions conceived, so that, thanks to the substantial help of the robotic handling automations, each reality can make the qualitative and quantitative operation of its machinery as efficient as possible.

The Arcos team is always ready to face new challenges, so don’t hesitate to contact us: together we will find the most suitable solution for you