To be successful in the industrial market it is no longer enough to differentiate yourself from competitors in terms of product quality and the range offered, but it is extremely essential to operate to increase the productivity of your plants.

Before being able to optimize the productivity of your supply chain, it is necessary to carefully analyse the ways and times in which the entire activity is performed so that you can have a measurable data with which to identify the level of productivity of your company. To carry out a complete analysis of the Work cycle times, the entire production process should be divided into operations which in turn must be divided into phases: the set of phases generates the Cycle Time or the amount of time that elapses between occurrence of an event and its repetition.

Applying this method to Lean Production concepts allows you to implement a conscious and targeted optimization of production processes: having a precise metric on how much time is spent making a product allows you to calculate the cost of labour and the relative cost of the single piece.

It is clear that the shorter the time taken to complete a cycle, the lower the internal cost will also be. How, then, to speed up the work cycle without affecting the quality of the piece produced? One of the most popular solutions in the era of Industry 4.0 is the automation of production chains, resulting in the possibility of managing the processes and machinery involved through control systems.

This approach allows to considerably improve the quality of the product especially in the processes that carried out manually would produce considerable quantities of waste and imperfections, thus reducing the quality of the product and consequently causing a lowering of the price. These processes include all surface finishing activities, such as grinding or sanding, which involve the use of complex and potentially dangerous tools.

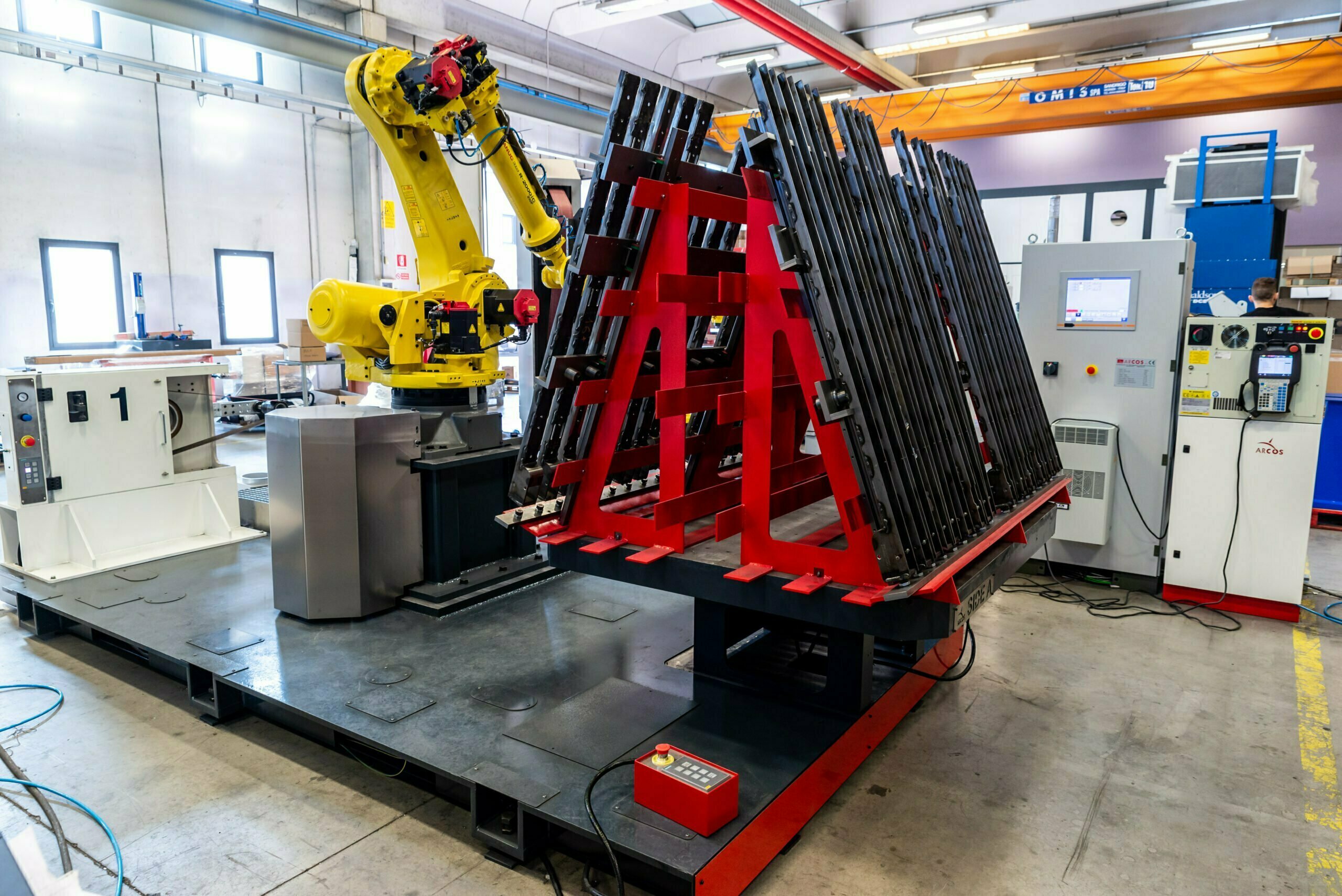

Thanks to the deep knowledge of the industrial sector and the needs of production companies, Arcos has been able to study and develop specific systems to support companies in the process of optimizing their productivity and has also identified specific machines for each of the industrial surface processes. In this article you can find out how to halve production times with robotic grinding automation.

Table of Contents

Automate the grinding process for the health of operators

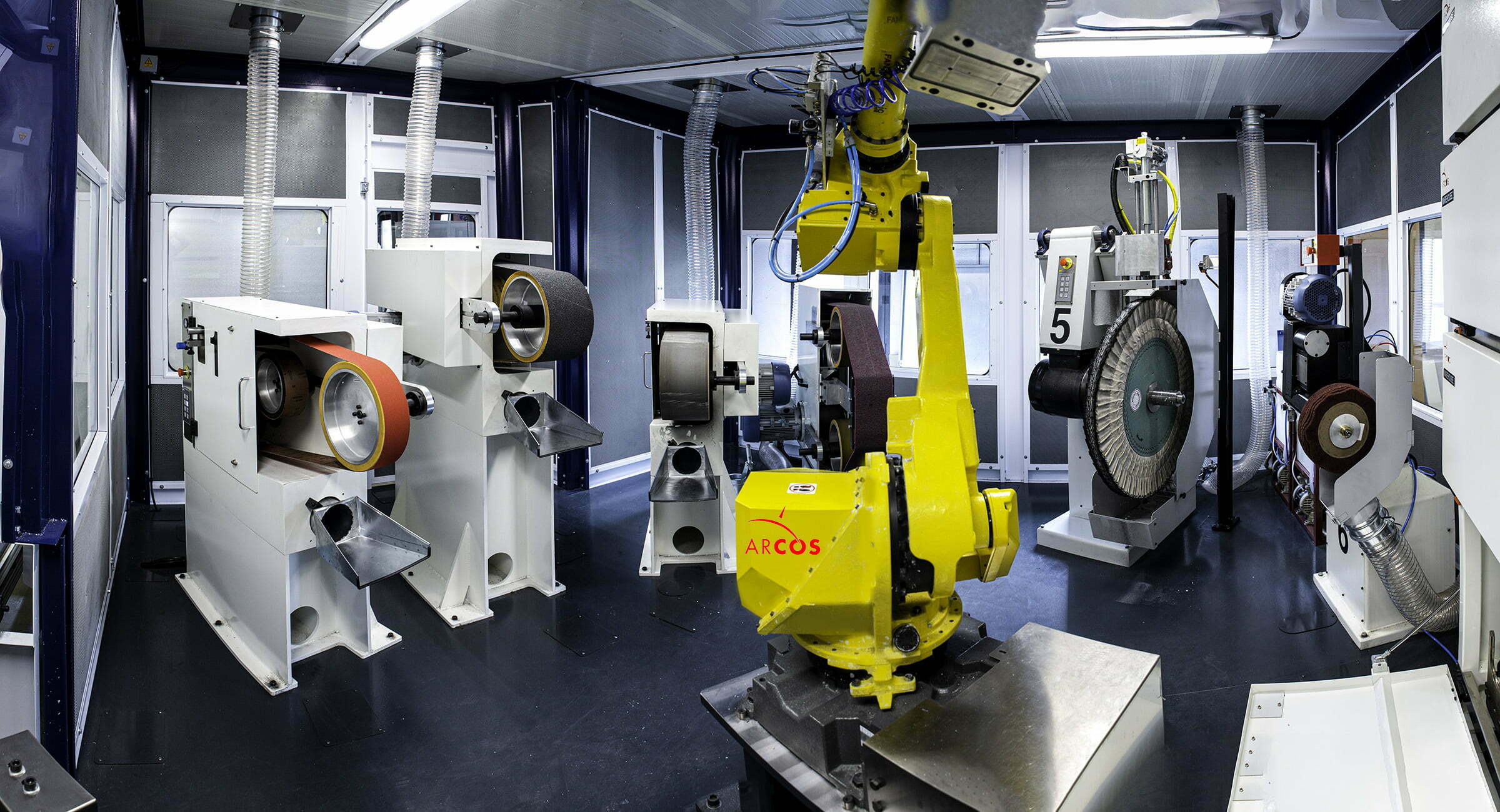

The use of automated systems is already widespread in most production systems, not only for the improvement of the quality of the finished product, but also because it allows the reduction of labour in harmful processes. Specifically, the grinding process requires a series of processes performed on pieces, even of complex shapes, using dangerous tools. In fact, most of the activity takes place on work surfaces or manual machines that use abrasive materials such as wheel belts or rigid tools, moved at high speeds.

The risks for the grinding operator can be different: accident risks such as trauma, lacerations or crushing caused by the handling of the pieces and falls; hygienic-environmental risks due to the dispersion of dust during the grinding cycle; occupational diseases caused by repetitive work and manual handling of loads, injuries to the hearing system, respiratory diseases and diseases caused by the vibration of tools.

An automated system considerably reduces the risks generated by manual grinding both in practical activity and in the side effects of processing: the robot performs the work in a protected environment, a cabin, with a dust extraction system.

Automate the sanding process to increase productivity

The use of machinery for product handling and subsequent processing allows for accurate and repeatable processing, giving the whole process standardized and previously measurable characteristics.

Regarding the measurement of the cycle time, there are some considerations to keep in mind before comparing the manual work to the robotic one: by examining each of the phases that make up the operations of the entire production process and comparing them with the same carried out in automation, in some cases the manual work cycle may be better. This does not mean that the entire manual cycle time is better than automated production, but that the single phase is carried out faster than the robot. In these cases, even if the robot takes longer in the single phase, it then reports shorter times in completing the entire cycle.

This applies in those cases in which the robot is programmed to replicate the manual activity, using its potential incorrectly: the automation of the finishing processes allows the use of different technologies, compared to those that can be used manually, which allow to optimize the finishing process.

Furthermore, the automation allows to reduce the unproductive times in which a piece passes from one manual workstation to another, ready to continue the next processing phase, carrying out in a single phase and with a single “arm” the entire processing cycle. In this way the Cycle Time is reduced, the quantity of waste produced is reduced and the quality and quantity of compliant pieces increases.

In Conclusion

The design and construction of an automation system for a specific production cycle certainly requires a considerable initial investment also in terms of staff training and adaptation of the previous production system. However, a high return on investment (ROI) index and the decades-long duration of the system justifies the initial cost: unlike the production carried out manually, the robot can do the work 24/24, with the same production quality, with predictable performance and replicable in the long term and performing complex machining even on bulky pieces or with inaccessible areas.

Arcos constantly works to offer innovative technologies and solutions suitable for each application sector, if you also want to accelerate the production innovation of your company, do not hesitate to contact us: the Arcos team will be at your disposal to guide you towards the best system for your business.