Companies that decide to rely on a robotic system for cutting excess material are constantly increasing. Robotic automations represent an avant-garde that guarantees considerable advantages in many areas: productivity is significantly increased by eliminating downtime and working without time limits, while the workforce – increasingly difficult to find – is spared from work that is often risky by carry out manually.

What are the different robotic cutting systems available? How to choose the best one for your needs and for the type of material to be processed? Find out in this article, through the advice of Arcos: for years engaged in the development of the best technologies to produce advanced robotic systems.

Table of Contents

Advantages and customization: the different robotic cutting systems

Robotic cutting systems are extremely advantageous thanks to the precision and speed with which they apply the cut of an object. In addition to this, their use greatly reduces the possibility of cutting errors and limits product waste compared to manual work. The operators are also benefited, who are placed in greater safety by carrying out their duties in non-hazardous areas.

Precisely because they must adapt to the type of material and shape of the object to be processed, these systems can be customized to meet the individual needs of each reality. For this reason, three types of systems can be mainly distinguished, based on the type of cutting tool that is used:

- Cutting system with abrasive disc.

- Cutting system with tape or circular blades.

- Plasma cutting system.

Let’s go into the details of each system to understand which materials it is mainly suited to and what needs it can meet.

1 # Cutting with abrasive disc

Cutting with an abrasive disc is useful and effective when there is a need to cut very hard materials, more tenacious than others, such as Inconel® cast iron and heat-treated steels.

2 # Cutting with tape or circular blades

Cutting with tape or circular blades is particularly suitable for processing softer materials, such as steel, wood, brass and aluminium.

3 # Plasma cutting

When the shape and geometry of the object to be machined do not allow the use of blades or discs, plasma cutting is the best solution.

Robotic plasma cutting is applied using high-speed ionized gas, called plasma, which heats and melts metals. The plasma mechanically blows away the molten material to cut the workpiece. It can alter the metallographic properties of the material given the high temperatures reached, so a careful evaluation of the process must be carried out so that it takes place in total safety and with optimal results.

This cutting system is usually used for steel and non-ferrous materials: it lends itself very well to both very thin and thick metals, ensuring a high-level result. Through its application, in fact, high quality cuts are obtained with a high movement speed.

Plasma cutting robots can create large angular or curved shapes, as well as smoother surfaces than with manual application.

Especially when cutting thick elements, it is possible to run into some errors during processing. The main ones can be linked to the formation of burr, to a so-called “V” cut, to an incomplete or low-quality cut.

To solve and remove these defects it is necessary to apply surface treatments, of which Arcos is highly qualified. In this way it is possible to offer the customer an all-round service that allows him to obtain a finished product internally, without having to outsource operations. Let’s go into the details of this advantage through the path of growth and awareness that over the years has led Arcos to offer this service.

The experience of Arcos

Arcos, which has always placed its customers at the center of its project, in order to offer a better service and respond to different needs, has decided to integrate skills that would allow it to expand the Arcos service portfolio.

The company has always had a deep-rooted history in the surface finishing sector and was born as a manufacturer and distributor of manual cleaning machines. With the advent of automation, Arcos has intertwined its history with new realities and with a new type of clientele with diversified needs.

Internalization and integration of processes

If companies usually preferred to outsource the cleaning and grinding of parts, because it was considered a tiring, expensive task and that required great technical skills, with the introduction of robots and the possibility of automating this process, the common choice fell on the internalisation of the various operations.

Arcos was thus able to offer its contribution in the production sites where components were made for third parties. By introducing its own reality within these large factories, such as steel mills, foundries, printing works, laminators, and others, it was possible to clearly see the countless processes to which the products are subjected, which were not limited only to the operations of grinding and polishing.

Customers needed to integrate all operations into a single process, reducing time and costs, with the possibility of increasing production: from here Arcos decided to guarantee and offer a 360 ° service. This is how the interlocking, palletizing, assembly, quality control, threading, drilling, and cutting operations are born, for an ideal and tailor-made integration for each company, in response to all its needs.

Some concrete examples: Arcos case studies

The areas of application of a robotic system for cutting can be many and, thanks to the different tools used, it is possible to respond to each one in an impeccable way.

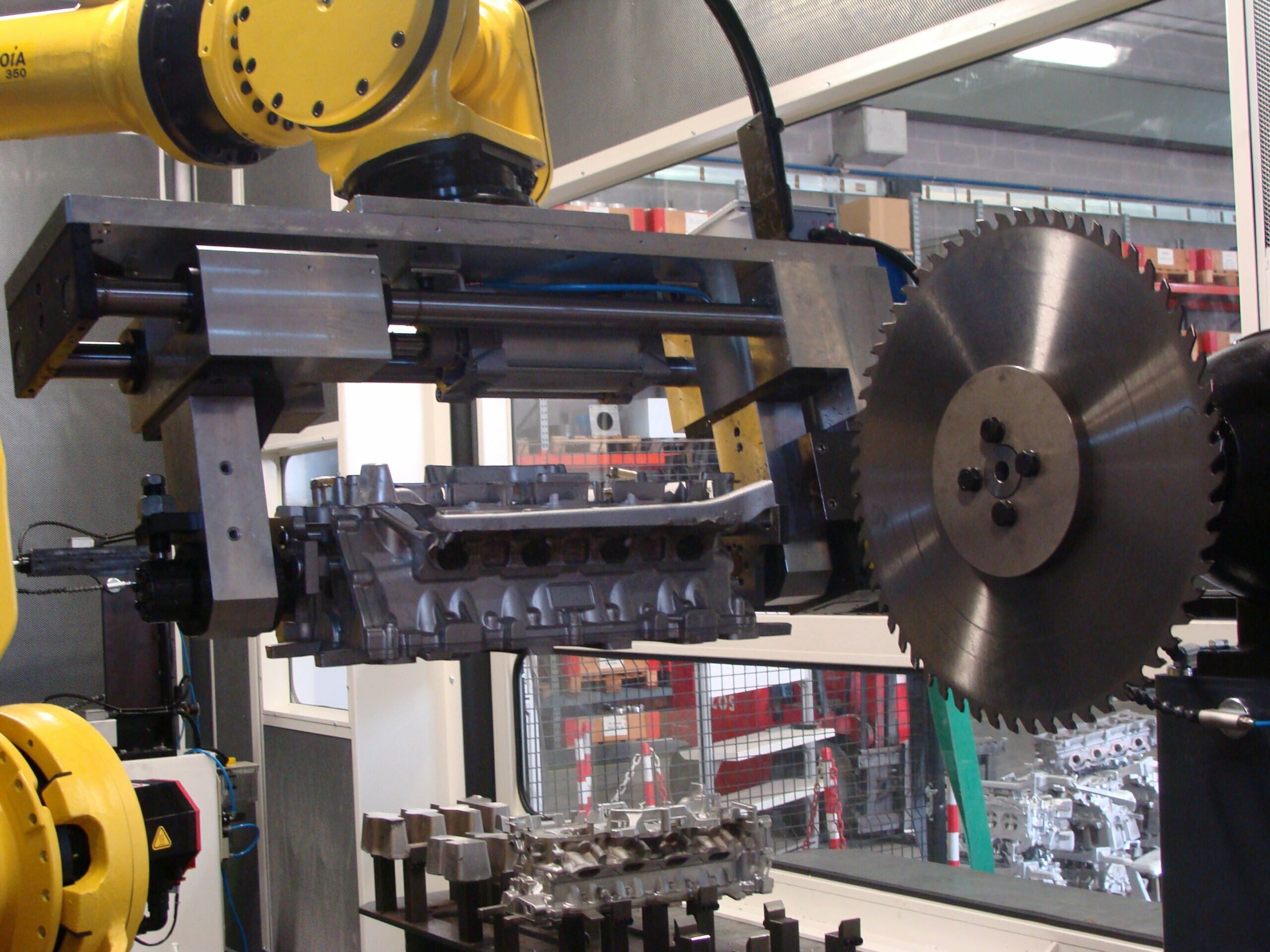

In this video you can observe two different systems in action: cutting work with a 1000 mm diameter disc, in addition to precision cutting applied with plasma technology to aeronautical parts.

Hydraulics and agriculture? Arcos robotic systems are also perfectly suited to these sectors: here you can see how the machining burrs are removed from aluminum parts, to then be sanded and cut according to the required piece in total autonomy.

Arcos finds a particular feeling with small / medium-sized foundries and printing works. In these areas, in fact, components of various types and sectors are made, with the same need to remove the sprues from the details, or the sprues where the metal or plastic is inserted inside the molds.

Within this case study, the cutting system was designed and developed for cutting large sprues and diversified shapes, intended for the energy industry.

Conclusion

A robotic cutting system turns out to be of enormous benefit within many areas. Through its use, in fact, it is possible to make precise, fast, and safe cuts to a large variety of objects, which can be differentiated by shape, weight and material. On the basis of these characteristics, in fact, it is possible to prefer the most suitable cutting system, choosing between: an abrasive disc for the hardest materials, a belt or circular blade for the softer materials, and plasma in the presence of objects with geometries more particular and articulated. In any case, the result will be excellent, with time savings dictated by an increase in productivity.

Arcos offers all these robotic cutting systems, studying the best solution for each company from time to time. Do you want to understand which system is best suited to your reality? Contact us: our team will help you find the right solution for you.