In the furniture and design sector Arcos has developed several surface finishing projects: smoothing, grinding and polishing of objects of any material. Read the Arcos case studies below!

STUDY CASES FOR THE FURNITURE AND DESIGN SECTOR

ROBOTIC SYSTEM FOR THE GRINDING OF TAPS

This robotic system is designed to automate the tap grinding process. It has great elasticity thanks to the two triple grinder units and the pliers designed to reproduce all human movements.

Robotic system for sanding wooden surfaces

The robotic system is designed to guarantee an automatic sanding of the wooden surfaces of different objects. The robot can be adapted to different shapes and sizes.

Robotic system for grinding aluminium articles for furniture

This robotic system is designed for grinding aluminium articles for furniture.

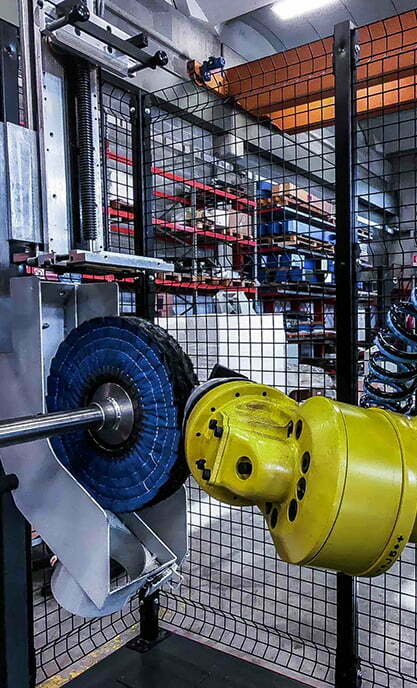

Robotic system for the polishing of aluminium articles for the furnishing industry

The Robotized System allows the automatic polishing of aluminium articles for furniture. The system is equipped with loading and unloading of the component in a totally automatic way.

– 1 Six-axis robot FANUC M70Ic/50M;

– 1 PU9 double cleaning unit;

– 1 Double cleaning unit PU5;

– Loading/unloading system with rotary table;

– 1 Kit of grippers for clamping 10 pieces;

– 1 Electric cabinet with control panel;

– 1 Safety laser scanner SICK MS3;

Protection nets.

Pieces: Hinges for furniture

Material: Extruded aluminum

Operations: Polishing of aluminum parts

ROBOTIC SYSTEM FOR THE SATIN FINISHING OF KITCHEN HOODS

The robotic cell automates the satin finishing process of stainless steel kitchen hoods. The advantages are considerable, from management to process repeatability.

PLEASE CONTACT US HERE TO DISCUSS YOUR PROJECT

Arcos assists you in the world

ITALIA E WORLDWIDE

8:00 – 18:00

Via Leonardo da Vinci, 15/C 25064 Gussago (Bs) Italy

NORD AMERICA, CANADA E MESSICO

8:00 – 18:00

30 Chapin Road Suite, 1205 Pine Brook, NJ 07058 – USA