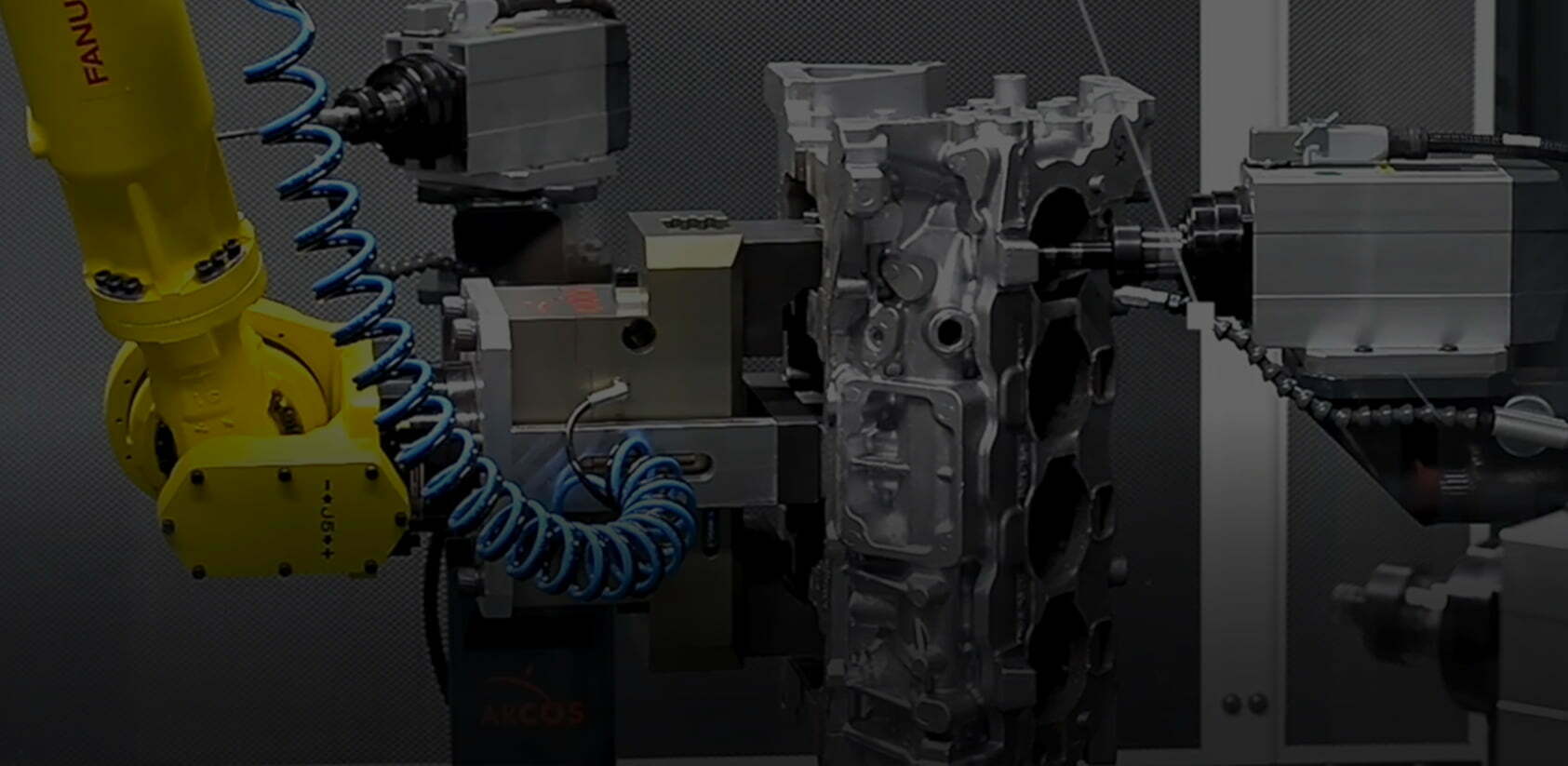

Automated robotic cutting systems

Precision and efficiency

Versatility across materials

CUTTING

CASE STUDIES FOR CUTTING

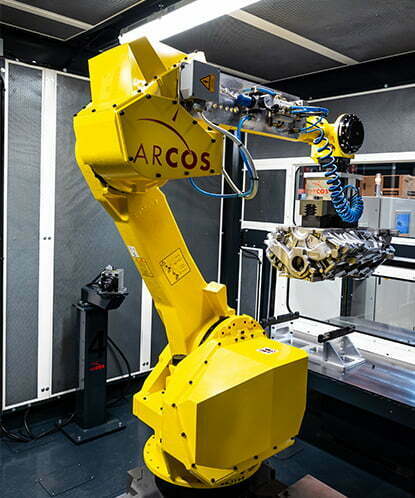

Robotic system for grinding and cutting with disc, precision cutting with plasma technology of aeronautic details

This robotic system is designed for finishing aeronautical details. Allows grinding and cutting with 1000 mm diameter disc or precision detail with plasma technology.

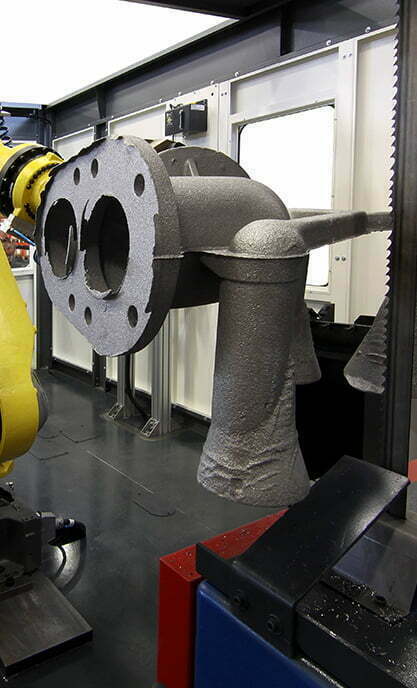

Robotic system for the cutting of sprues on large pieces for the energy industry

The robotic system is designed for cutting sprues on large pieces and different shapes for the energy industry.

RECOMMENDED MACHINES FOR CUTTING

ROBOTISED SYSTEMS

Type of Materials

cast iron

glass

aluminum alloys

Steel/stainless steel

brass

Zamak

hard stones

titanium alloys

Inconel ®

magnesium alloys

composite materials

Plastic