Arcos Centerless Machines for surface finishing represent the best solution for polishing and grinding of tubes and bars with circular section. The centerless solution is designed to considerably increase the productivity of circular section elements with simple geometric characteristics. Arcos solutions guarantee roundness and surface finish according to customer requests. Like all Arcos automatic machines. Centerless machines are characterized by great robustness, reliability, ease of use and use of cutting-edge technology.

FEATURES OF OUR AUTOMATIC CENTERLESS GRINDING MACHINES

CASE STUDIES FOR CENTERLESS MACHINES

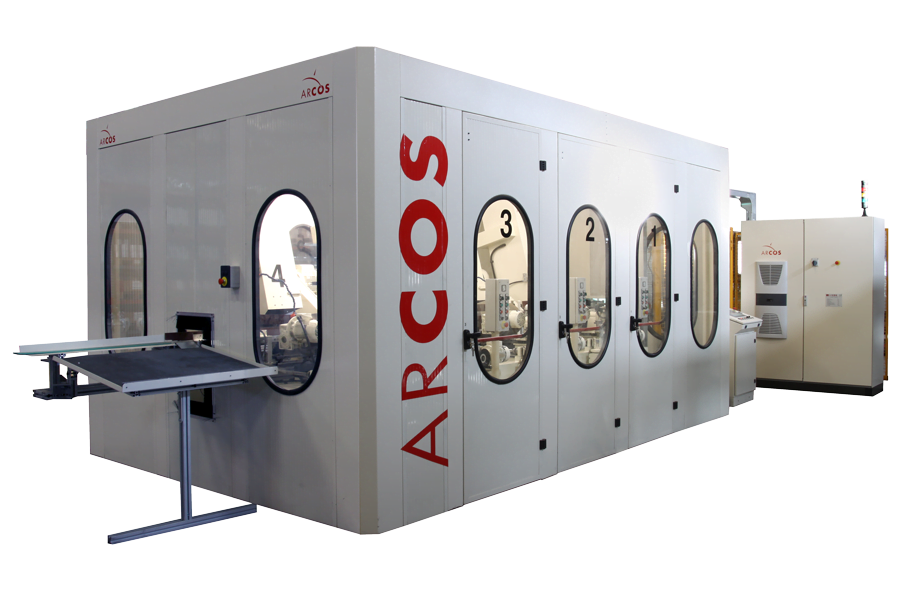

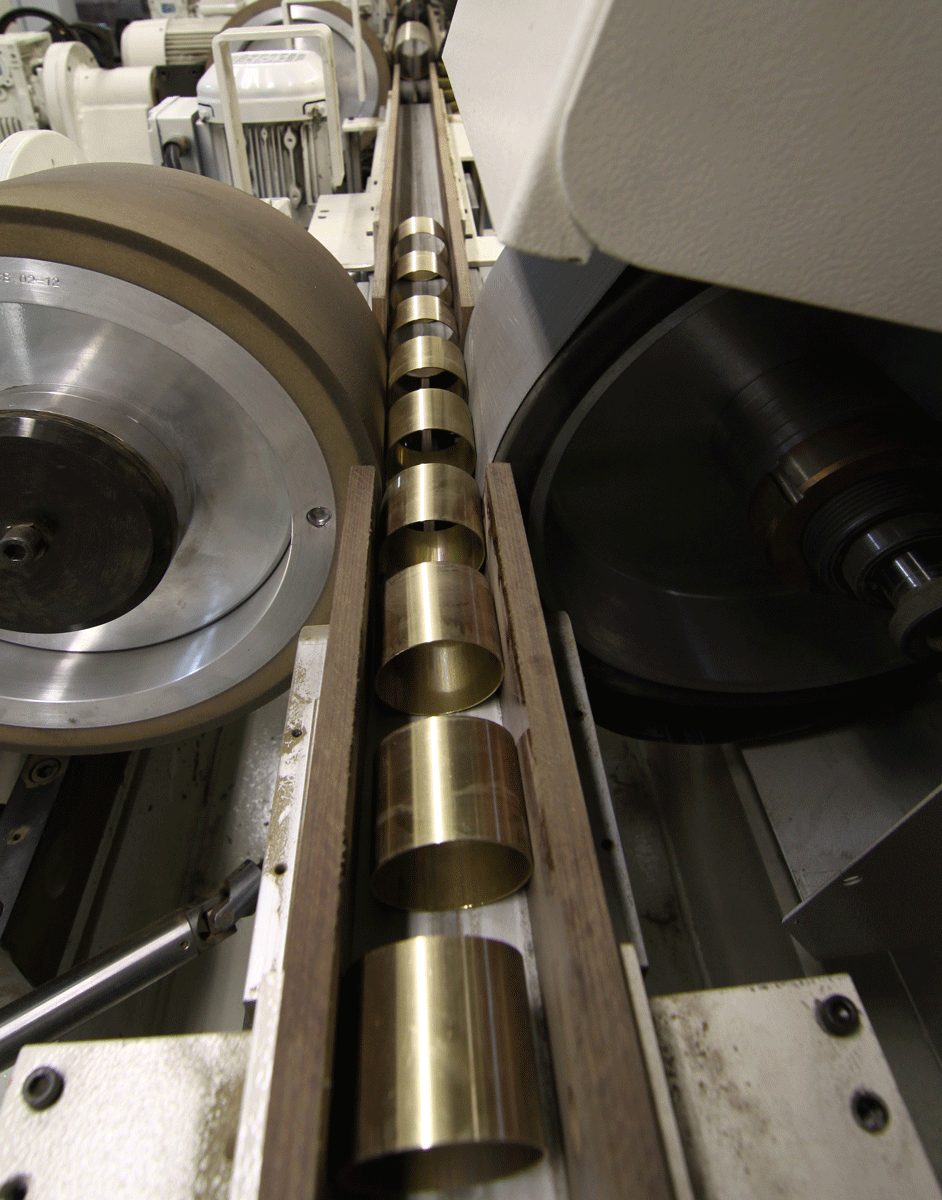

Automatic centerless machine for grinding brass pipes

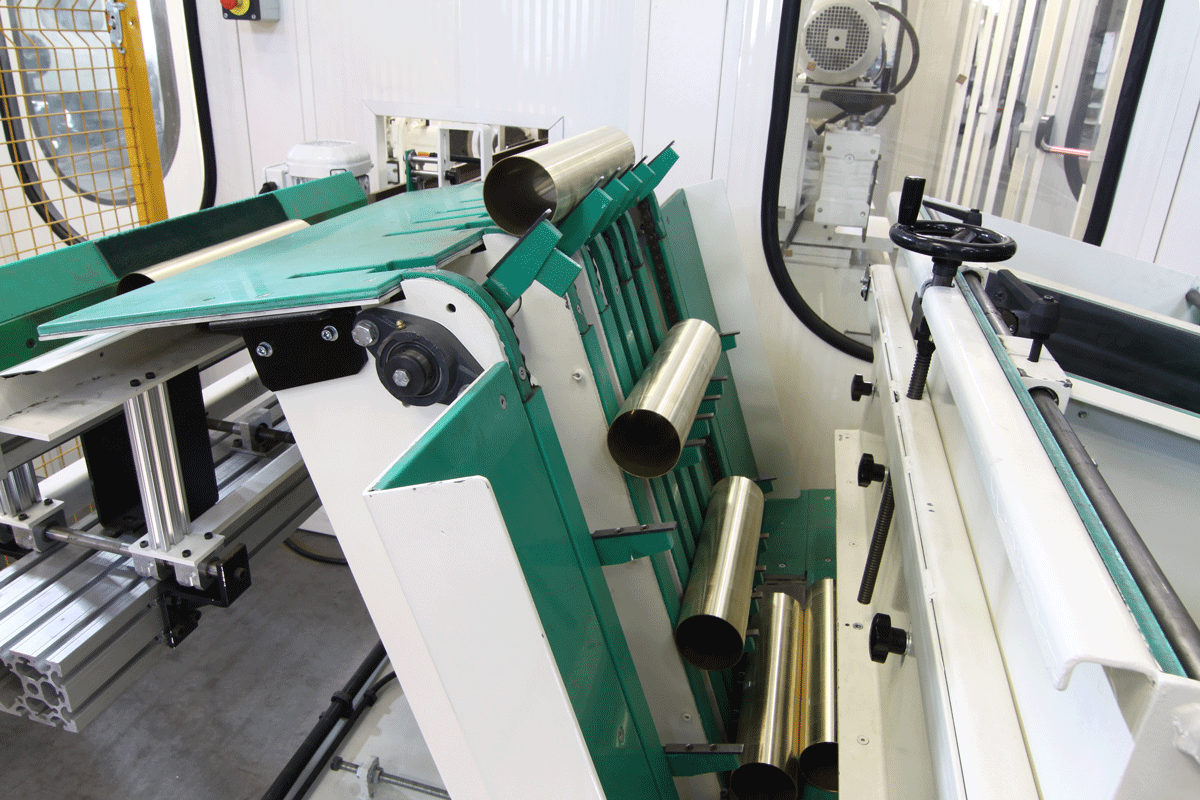

The centerless machine allows automatic grinding of brass pipes, by loading the raw product and automatically unloading the finished product.

• grinding units convertible into polishing

• automatic tube loader

• automatic adjustment of tube diameter and length

• tube feeding system with vibration of the pieces

• soundproof cabin

• Remote Support

• possibility of working with pipes with a diameter from 6 to 100 mm and a minimum length of 50 mm

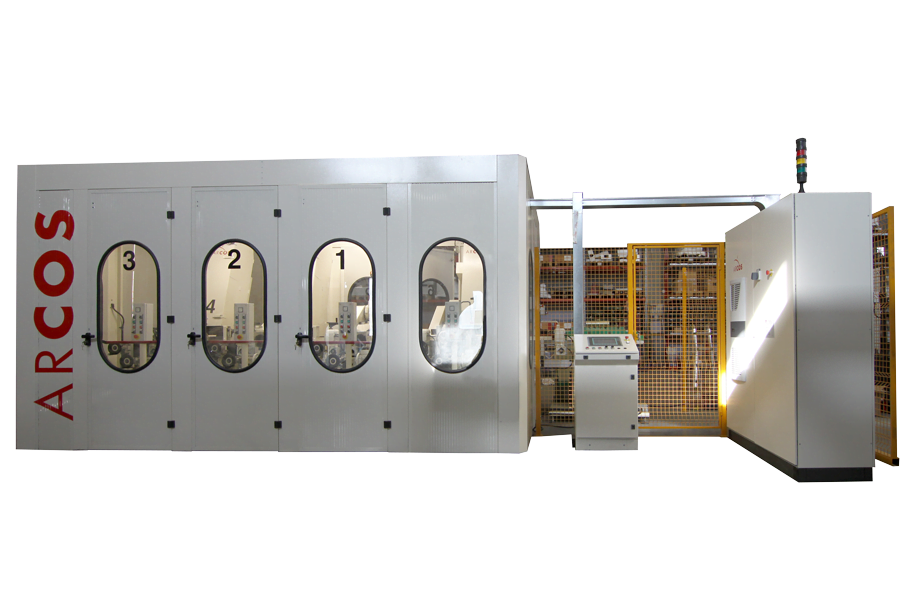

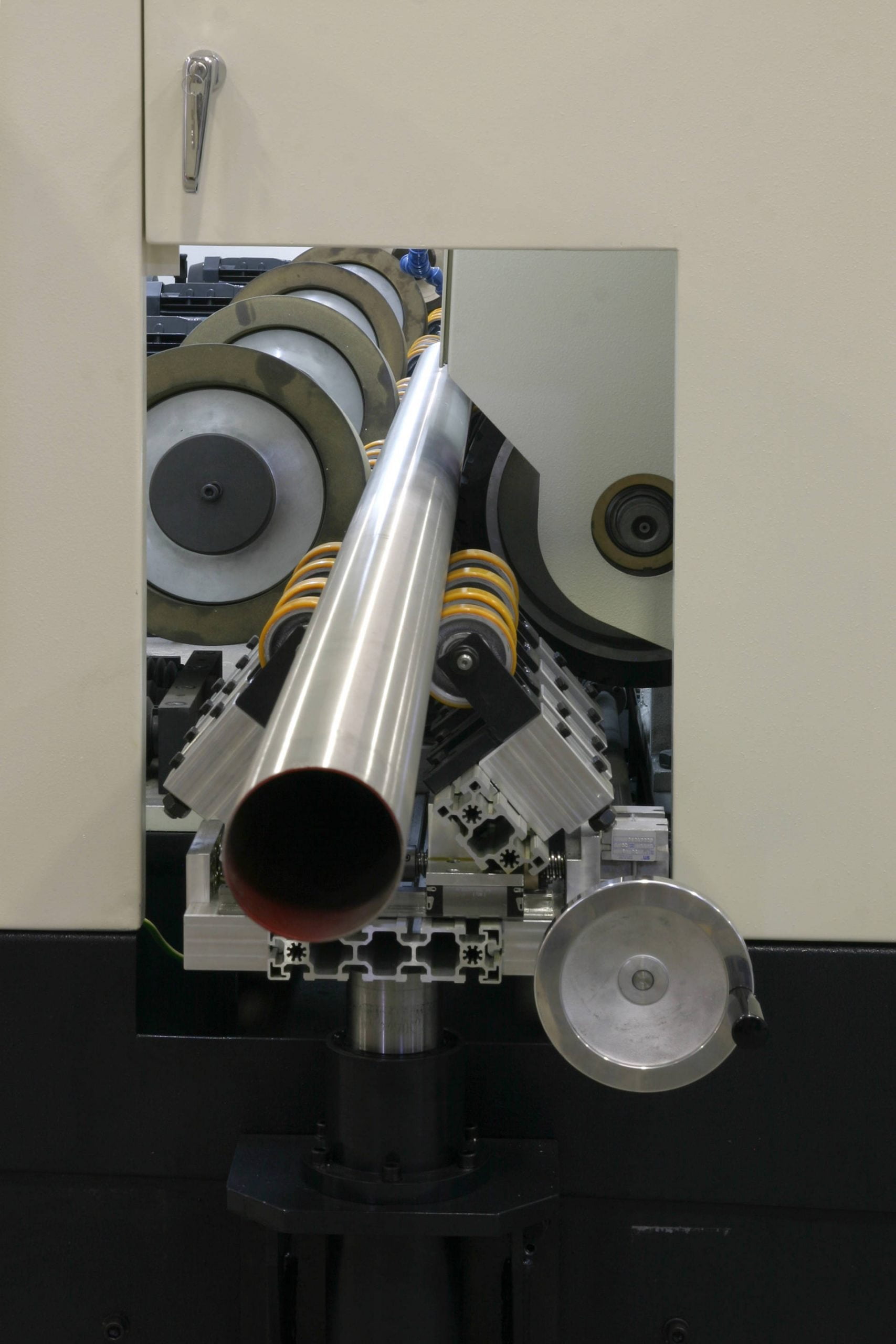

Centerless machine for grinding steel pipes

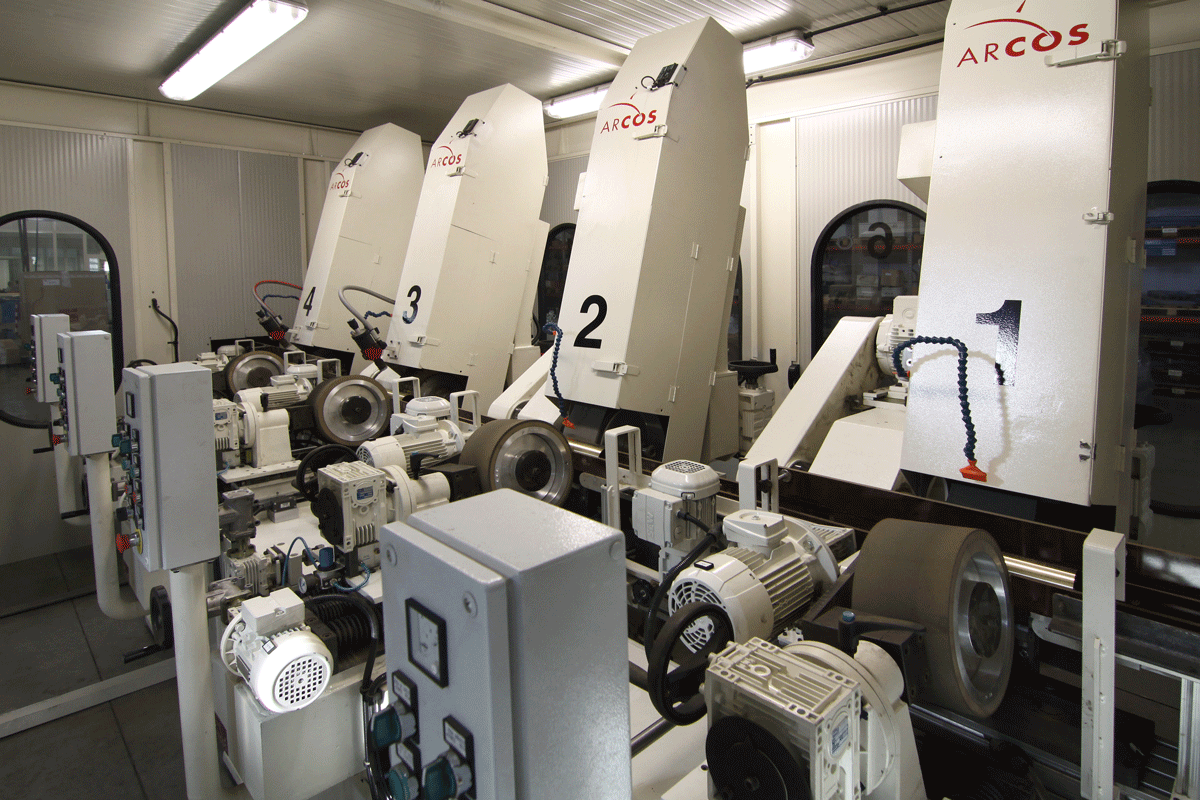

The centerless machine allows automatic grinding of steel pipes through 4 units, by loading the raw product and automatically unloading the finished product.

• 4 units for grinding with abrasive belt

• automatic adjustment of tube diameter and length

• tube feeding system with vibration of the pieces

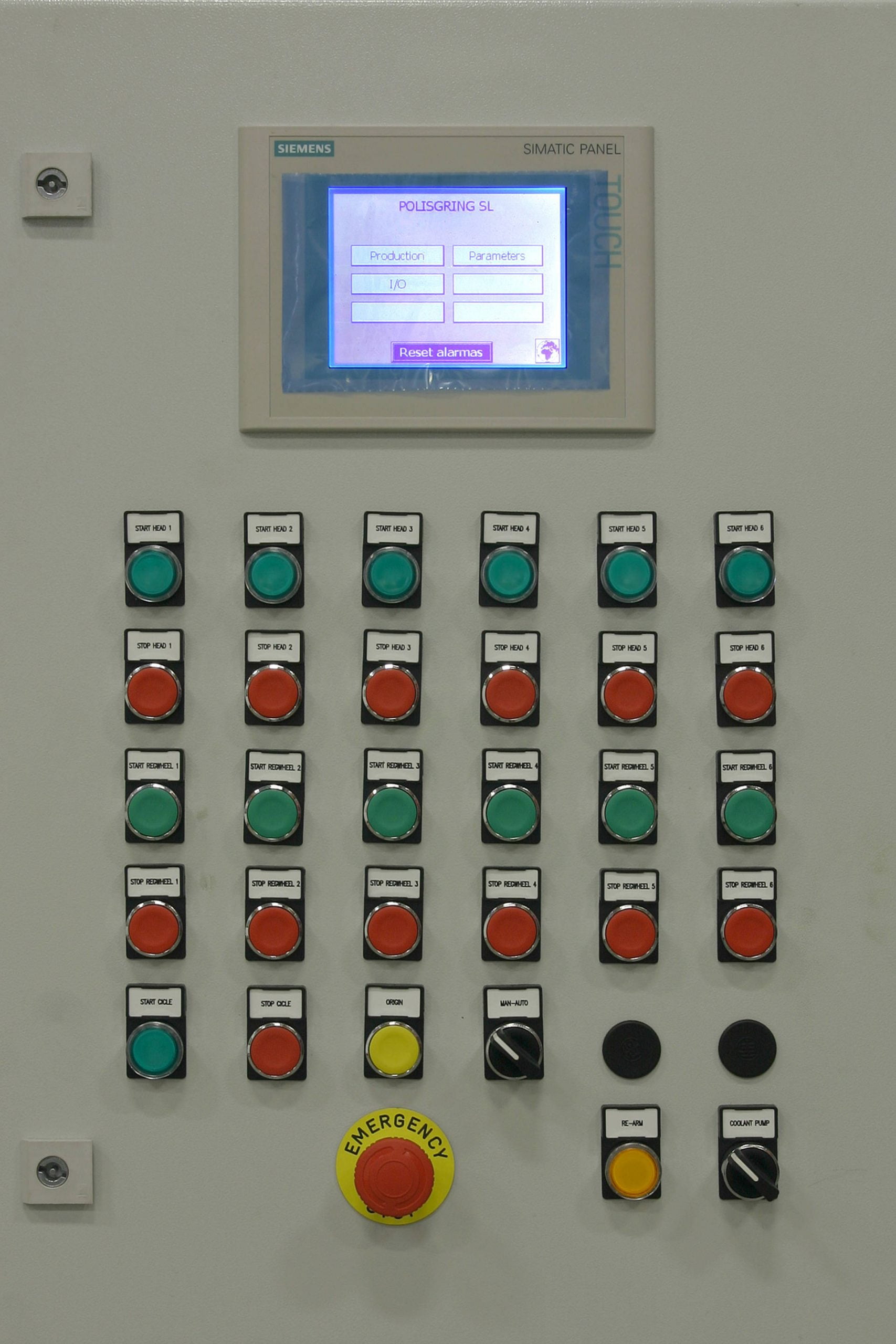

• supervisor control panel

• monolithic base

• possibility of working dry or wet

• soundproof cabin

• possibility of working with pipes with a diameter from 6 to 200 mm and a minimum length of 1000 mm