The rapid growth of the aerospace sector, due to the increase of commercial flight operators and the increase of innovations in the defence’s field, requires suppliers to increase production. To respond to market globalization, increasingly qualified competition and extremely high and inflexible standards, the aerospace industry must re-evaluate the production processes to increase efficiency, reduce timing and costs and ensure products of excellent quality. To achieve this result, which is as ambitious as necessary, an increasingly intense shift is taking place from manual processing centers to efficient automated cells that optimize production.

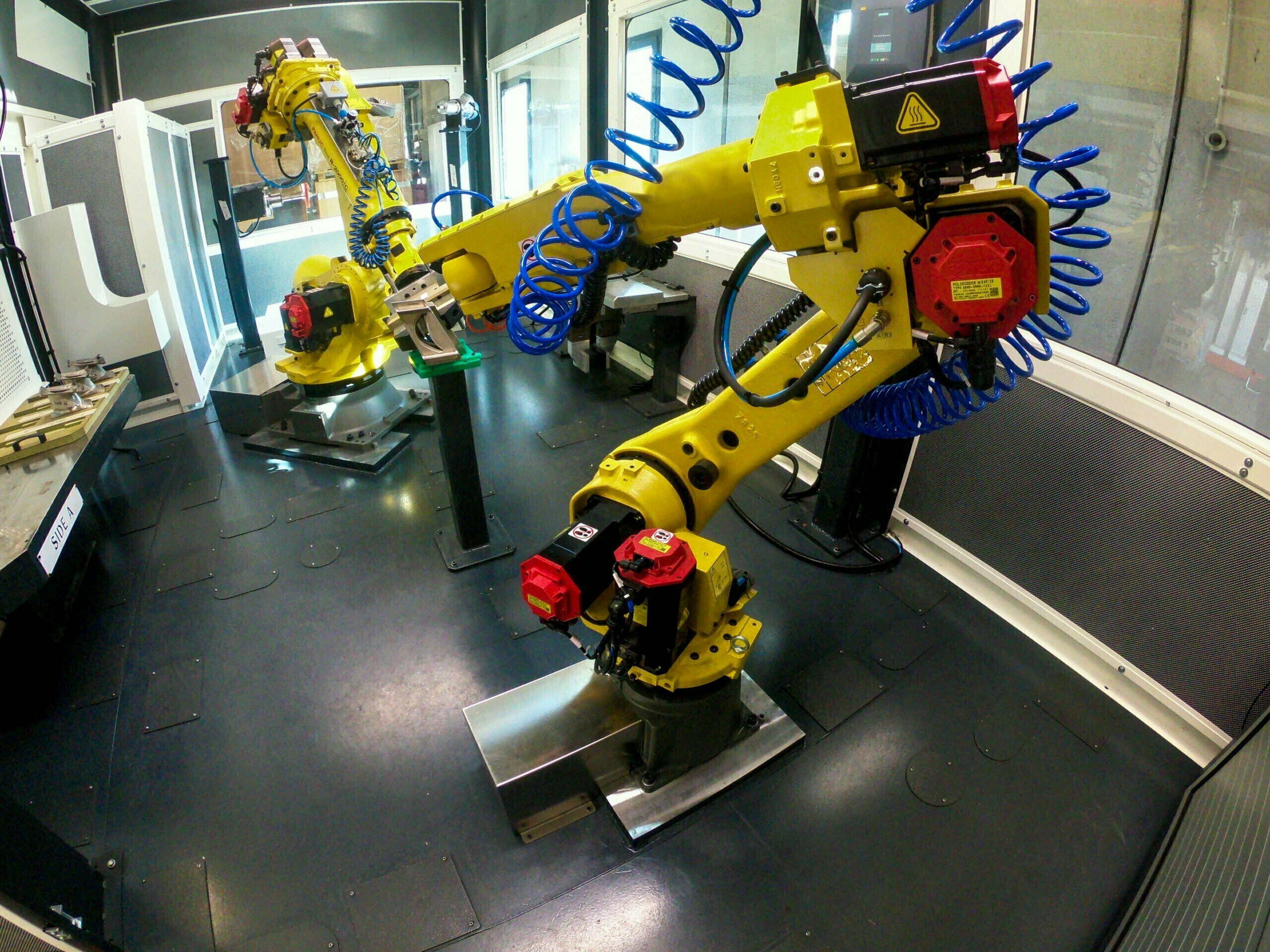

The introduction of automation in industrial sectors makes it possible to obtain extremely high levels of precision and quality, capable of satisfying the essential safety criteria necessary to be able to use the pieces and components on aerospace aircraft. By entrusting robotic technology with important activities that have always been carried out under human control, such as the procedures for verifying the dimensions and conformity of the machined surfaces, it is possible to assign control to artificial vision, virtual prototyping or scanning and calculation systems. Thanks to these technologies it is possible to speed up the entire supply chain, approaching absolute quality.

The benefits of using robotic systems in the aerospace industry do not only concern the quantity and quality of the produced parts, but also the health of the workers. In fact, the work processes related to this type of sector are not without risks, especially due to inhalable dust as a result of finishing processes or accidents attributable to the use of heavy and dangerous tools and machinery.

From years of experience and important collaborations in the aerospace sector, Arcos has developed a deep knowledge of the sector and its quality needs, and created avantgarde systems for the processing of components of aircraft in flight and of the objects that make up vehicles for the transport of people and goods.

In this article, Arcos explains which services can support companies in this sector and which are the best technologies for aerospace grinding.

Table of Contents

Technologies for aerospace grinding according to Arcos

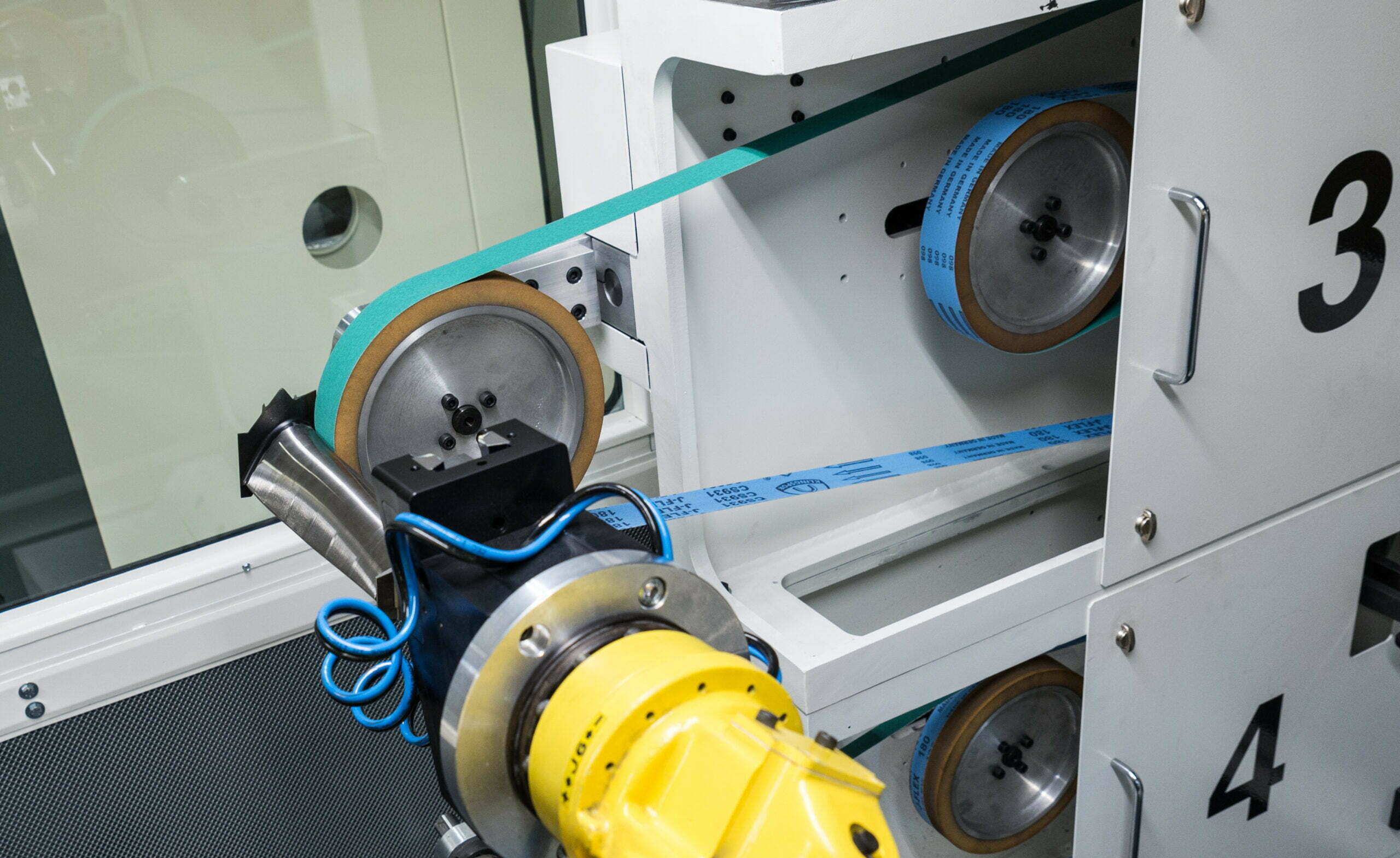

Grinding or sanding is generally the preparatory operation for surface treatments that allows the surface to be improved through a series of abrasive material’s passages and with a sequence of grits with different degrees of abrasiveness. Arcos has created various machines for grinding various types of materials and objects, adapting the instruments and systems to each particular situation and need. The aerospace sector requires an high degree of precision from this operation due to the machining of fundamental components for the safety of the aircraft such as turbine blades or aircraft engine components. Being a sector that requires machining with close tolerances for applications, Arcos has studied its technologies so that the precision of the machining is monitored by scanning and calculation systems included in the system.

Generally the turbine blades that are destined to undergo a precision finishing are obtained by 4 different processes: machined from solid, or rather by mechanical processing; by additive manufacturing, or rather through 3D printing; by a forging process and a casting process, for these last a cut-off and sprues removal is needed. For each of the blades different problems arise, but all undergo a preparation for finishing with five-axis numerical control machines. Subsequently, therefore, it is possible to carry out the precision finishing process such as grinding or deburring and treat different areas to make the machined piece functional and safe.

Conclusion

The aerospace sector requires that grinding technologies have a high processing sensitivity to satisfy the need for absolute precision. To achieve this result, it is necessary to design the machining system so that the piece undergoes the same pressure throughout the entire grinding process. Arcos has developed a deep knowledge of the needs and safety requirements that the aerospace sector requires from suppliers and manufacturers and has developed machines for the automation of finishing processes capable of meeting the highest demands.

To support customers even after the commissioning of robotic systems, Arcos offers an assistance service that includes remote assistance and on-site assistance for support in case of malfunctions, implementations, or the need to receive spare parts or consumables. It also takes care of training operators for an impeccable use and management of automatic systems. Arcos is always on the front line to propose new innovative projects, if you want to be part of this technological revolution too, do not hesitate to contact us, Arcos team will be available for all your projects.