Grinding aluminum is a critical phase in the manufacturing processes of many companies, especially those involved in producing components for the aerospace, automotive, and electronics industries. This process is crucial for achieving smooth, uniform, and impurity-free surfaces on aluminum parts while ensuring maximum precision and quality.

In this article, we will explore the primary needs in aluminum grinding, different methods to carry it out, and why an increasing number of companies are turning to automated solutions, such as those developed by Arcos, a leader in custom robotic surface finishing solutions.

Table of Contents

Why Aluminum Grinding is Necessary

Aluminum grinding is a crucial phase in company manufacturing processes for several reasons:

- Enhancement of Physical Characteristics: It removes surface impurities, improving the wear resistance, durability, and corrosion resistance of aluminum parts.

- Geometric Precision: It ensures the geometric precision of components, ensuring they are accurately sized and meet the required quality standards.

- Aesthetics: It provides a better aesthetic appearance to aluminum parts, making them more attractive to end-users.

- Compatibility with Subsequent Processes: A well-ground surface can facilitate subsequent processes like painting or welding.

Methods of Aluminum Grinding

There are several methods to perform aluminum grinding; let’s look at the main ones.

Manual Grinding

This method involves human intervention, with skilled personnel using manual tools like angle grinders or hand sanders to grind aluminum parts. While it can be effective, it is labor-intensive and subject to variables related to the operator’s skill, resulting in longer work times compared to automated technologies.

Mechanical Grinding

In this case, grinding is carried out by specialized machines. This method is more consistent than manual grinding but still requires operator supervision throughout the process.

Automated Grinding

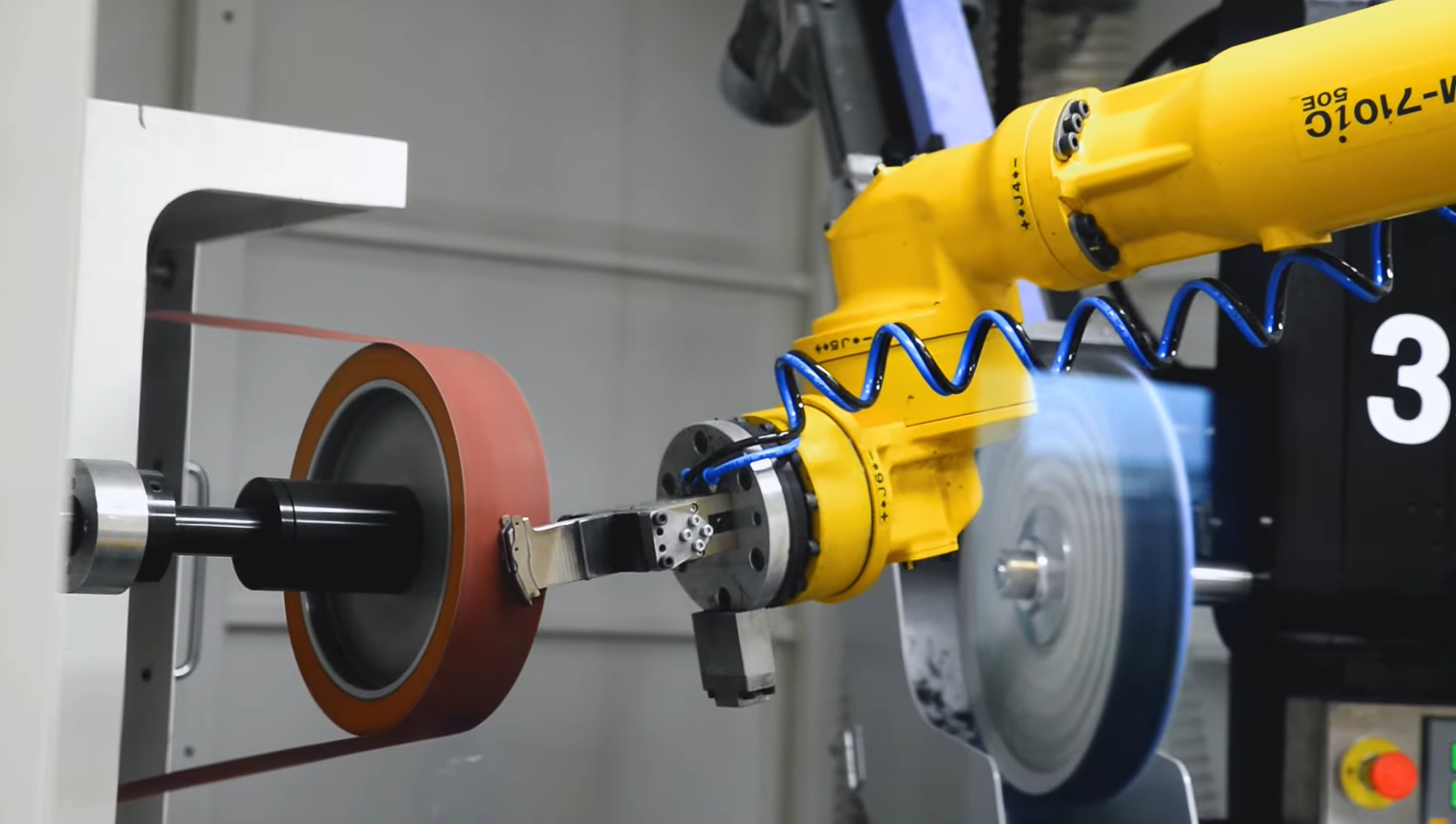

This is the most advanced and reliable method, involving the use of robotic systems to perform aluminum grinding. These systems can be fully automated and controlled by software to ensure maximum precision and repeatability.

Arcos Automated Solutions

In recent years, an increasing number of companies have turned to automated solutions for aluminum grinding, with Arcos being a prominent player in this field. Here’s why Arcos surface finishing technologies are among the best choices in the market:

- Maximum Precision: Arcos’ robotic systems are equipped with advanced vision and control technologies, ensuring incredible precision in aluminum grinding. This results in high-quality parts that meet the strictest standards.

- High Productivity: These installations can operate 24/7 without interruptions, ensuring continuous production and increased efficiency. This reduces downtime and operational costs.

- Reduced Operator Risk: By using automated solutions, the exposure of operators to hazardous and strenuous tasks is minimized. This improves workplace safety and enhances employee satisfaction.

- Customizable Flexibility: Arcos offers tailored solutions to meet the specific needs of each customer. This means you can configure the system based on the dimensions and specifications of the parts to be ground.

- Remote Monitoring: It is possible to monitor and control the systems remotely, allowing for effective remote management.

Conclusion

Aluminum grinding is a fundamental phase in company manufacturing processes, as it enhances component quality, durability, and aesthetic appeal. Arcos’ automated grinding solutions offer precision, productivity, safety, and customizable flexibility, making them ideal for meeting the needs of modern businesses. Every company can obtain its own highly efficient custom robotic surface finishing system.

With the continuous evolution of technology, the industry will continue to see increased adoption of automated solutions for aluminum grinding. Contact us to get a tailored solution for your business and stay up-to-date with the times.