Stainless steel is one of the most widely used materials in various industrial and domestic sectors, thanks to its corrosion resistance and robustness. However, to achieve maximum brilliance and a luxurious appearance, this material must undergo a mirror polishing process.

This mechanical processing allows obtaining a perfectly smooth and reflective surface, free of scratches, processing marks, and other imperfections. In this article, we will explore the main reasons why Mirror finish of stainless steel is performed, along with the machinery used and the advantages of adopting automated finishing systems in corporate production.

Table of Contents

Why is Mirror finish of stainless steel performed?

Mirror polishing is an essential process for several reasons:

- Aesthetics and Prestige: The mirror finish gives stainless steel a brilliant and luxurious appearance, making it ideal for applications where aesthetics are fundamental, such as in the furniture industry, high-end appliances, and medical

- Hygiene and Cleanliness: Mirror-polished surfaces are less porous and smoother, reducing the accumulation of dirt, bacteria, and organic residues. This makes polished stainless steel an excellent choice for applications in the food, pharmaceutical, and healthcare industries, where hygiene is of primary importance.

- Corrosion Resistance: Mirror polishing removes any impurities and oxides present on the surface of stainless steel, contributing to improving its corrosion and oxidation resistance.

- Easy Cleaning and Maintenance: Polished surfaces are easier to clean and require less maintenance over time, as dirt and residues adhere less to the smooth surface.

Machinery and mirror polishing process

Mirror finish of stainless steel is a meticulous process that requires specialized machinery. How does the process work? We can identify some general steps:

- Preparation: It starts with preparing the surface of the stainless steel, where any imperfections, such as scratches and processing marks, are removed. This is usually done through grinding or sanding.

- Polishing: After preparation, the stainless steel piece undergoes a series of polishing steps using increasingly fine abrasives. This helps to remove any grinding marks and achieve a smooth and uniform surface.

- Mirror Polishing: The next step involves mirror polishing, where the steel surface is polished with microscopic particles until an extremely high level of reflectivity is achieved, similar to a mirror.

- Final Cleaning: Once the desired level of polishing is reached, the piece is thoroughly cleaned to remove any abrasive residues and other impurities. At this point, the mirror-polished material is ready to be used or further processed if needed.

Advantages of automated mirror polishing

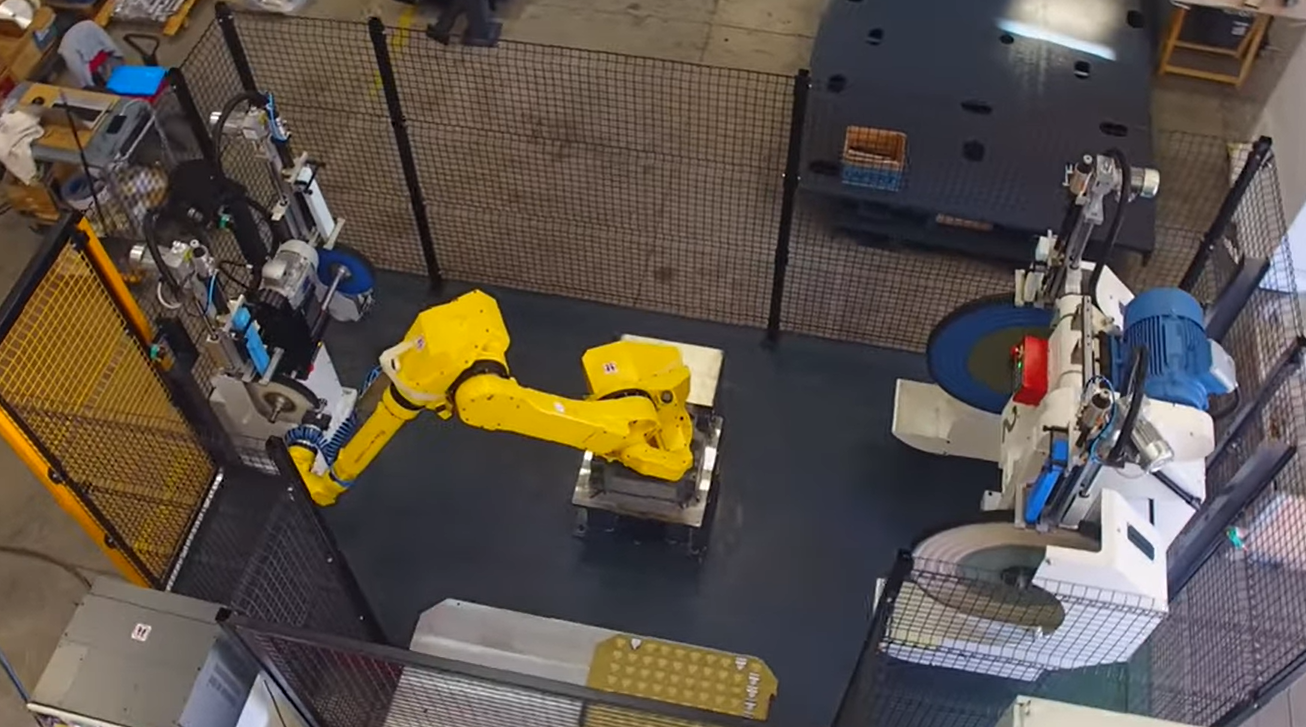

Mirror finish of stainless steel can be done manually, but it requires highly skilled professionals and an extremely time-consuming process. The use of automated machinery has proven to be the most advantageous solution for achieving consistent and high-quality results. Thanks to advanced technology, automation makes the process more efficient, reducing production times and labor costs while maintaining high standards of precision and repeatability. Automated finishing systems offer the following benefits:

- Precision: They can work with consistent accuracy, ensuring uniform and high-quality results on each piece.

- Speed: They significantly accelerate the polishing process, reducing production times and improving efficiency.

- Less Human Intervention: With automated machinery, fewer personnel are needed to supervise the process, reducing the risk of human errors and engaging staff in less strenuous and exhausting tasks.

- Repeatability: They can perform the same polishing sequence precisely, ensuring repeatable results on different production batches.

Moreover, mirror finishing not only enhances the aesthetics and functionality of products but also promotes sustainability. The increased corrosion resistance of mirror-polished stainless steel extends its lifespan, reducing the need for frequent replacements and contributing to waste reduction.

Thanks to automation, achieving high-quality results becomes efficient and economically advantageous. Whether for industrial applications or design projects, this process remains an essential step in creating excellent and long-lasting products over time.

Automated polishing systems by Arcos

To meet market demands and provide the most advanced automation systems for surface finishing, Arcos designs and manufactures tailor-made polishing systems for each individual requirement. From centerless machines to flat surface machines, Arcos’ polishing solutions are diverse but characterized by advanced technology and meticulous system study, resulting in unparalleled results.

For more information, here are some useful insights:

Conclusion

Mirror finish of stainless steel is a finishing technique that provides extraordinary elegance and increased durability to products made from this versatile material. Through automation, achieving excellence becomes efficient and sustainable, satisfying market demands and exceeding customer expectations. Investing in mirror polishing ensures a high-quality, durable, and flawless-looking product, contributing to the success and reputation of the companies that use it.

Would you like to learn more about Mirror finish of stainless steel? Contact us: one of our technicians will be happy to answer all your questions.