The prosthetic industry has experienced significant changes dictated both by discoveries in the medical sector and by technological and biomedical innovations. Just think of the modern custom prostheses built and osseointegration that allows you to connect the prosthesis to the nerves and muscles, or the super light materials used to allow fluid and natural movements.

The modern applications are the result of a long history of inventions that finds its origin in solutions initially built to hide amputations, made of rudimentary materials, but also of pioneering walking aids such as the prosthetic finger found in Egypt, dating back to the XXVII century a.C., and considered the first functional support to the movement.

To meet the new and higher standards, the medical industry has to rethink its production processes in order to increase efficiency, reducing time and costs, but still continuing to guarantee products of excellent quality. To achieve this result, it was necessary to introduce automated solutions that would allow us to respond to the inflexible quality demands of the market and optimize production with less waste of time and material. In fact, by giving important activities to robotic technology, which have always been carried out under human control, it is possible to reduce the risk of making any mistakes which, in such a delicate field, must correspond to a value close to zero.

From years of experience and important collaborations in the sector, Arcos has developed a deep knowledge of processes and devised cutting-edge systems for the processing of artificial prostheses, in full compliance with market needs and procedures. In this article, Arcos explains which services could support companies in this sector and in particular which are the best finishing technologies.

Table of Contents

The technologies for medical grinding according to Arcos

Today, medical implants are created by being able to choose from a wide range of materials and alloys, but the prevailing ones are titanium and stainless steel, sometimes even composite material. Prostheses intended to undergo precision finishing processes are usually created through one of the following manufacturing processes:

- Obtained from solid, or through mechanical processing;

- Formed through a growth process, or through 3D printing;

- Obtained from a hot forging process;

- Formed by a lost wax casting process;

- Printed with composite material.

After the formation of the semi-finished product, mechanical processing is carried out with a 5-axis machining center and, subsequently, the finishing process is carried out. This can take place through different processing stages but, generally, it concerns three main operations:

- grinding in 4 steps;

- tumbling;

- polishing in 2 steps.

The result of these finishing processes are perfectly finished and shiny products, as in the case of knee prostheses.

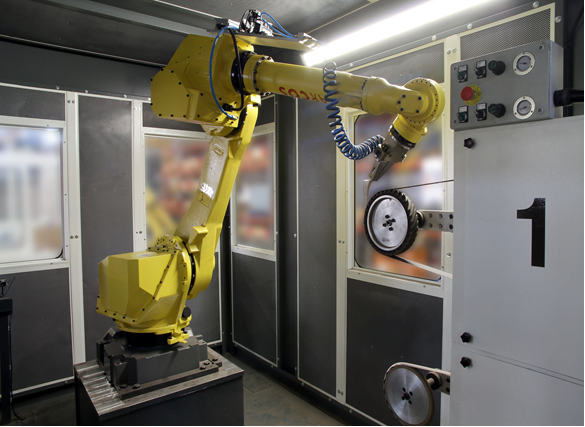

To achieve these results, Arcos offers robotic cells capable of providing the customer with a high degree of autonomy, thanks to a dedicated warehouse, and precision through a detailed study of its parts. In fact, the use of robots with off-set wrists allows for better handling and management of the piece – generally of small dimensions and complex geometries – allowing the robotic arm to work every detail without resorting to repositioning the grip. This translates into shorter cycle times and, consequently, higher production volumes.

Arcos units have a sensitivity that allows the user to manage the pressure and speed on each point of the surface to be machined instant by instant. Furthermore, by resorting to parametric or off-line programming Arcos is able to facilitate customers in programming new items without having to resort to hours and days of work inside the robotic cell.

Thanks to these characteristics, many activities for finishing medical prostheses can be integrated in a robotic cell, such as dot or laser marking or, better still, the measurement of some significant dimensions with optical or contact micrometers.

Conclusion

Thanks to the advent of microprocessors, robotics and precise mechanical processing, medicine has made enormous steps forward and has reached very high degrees of customization. The high-quality standards, the high technologies required, and the purposes of use make it very difficult for new companies to penetrate the prosthetic market, therefore, the participating companies live their presence with great honor.

Since 1965, Arcos has dedicated all its passion and knowledge to allow this sector to evolve and innovate, to create increasingly inclusive and performing prostheses for users. Being recognized as a competent and reliable company in the medical sector is a very important goal for Arcos, which continues to study with devotion innovative and quality solutions for this market.

To further support this delicate sector, Arcos offers an assistance service that includes remote assistance and on-site assistance for any need related to robotic systems, and for the supply of spare parts or consumables. It also takes care of training operators for the flawless use and management of automatic systems.

Arcos is always at the forefront to propose new innovative systems for the prosthetic sector, if you would like to be part of this technological revolution do not hesitate to contact us, the Arcos team will be at your disposal to give life to your project.