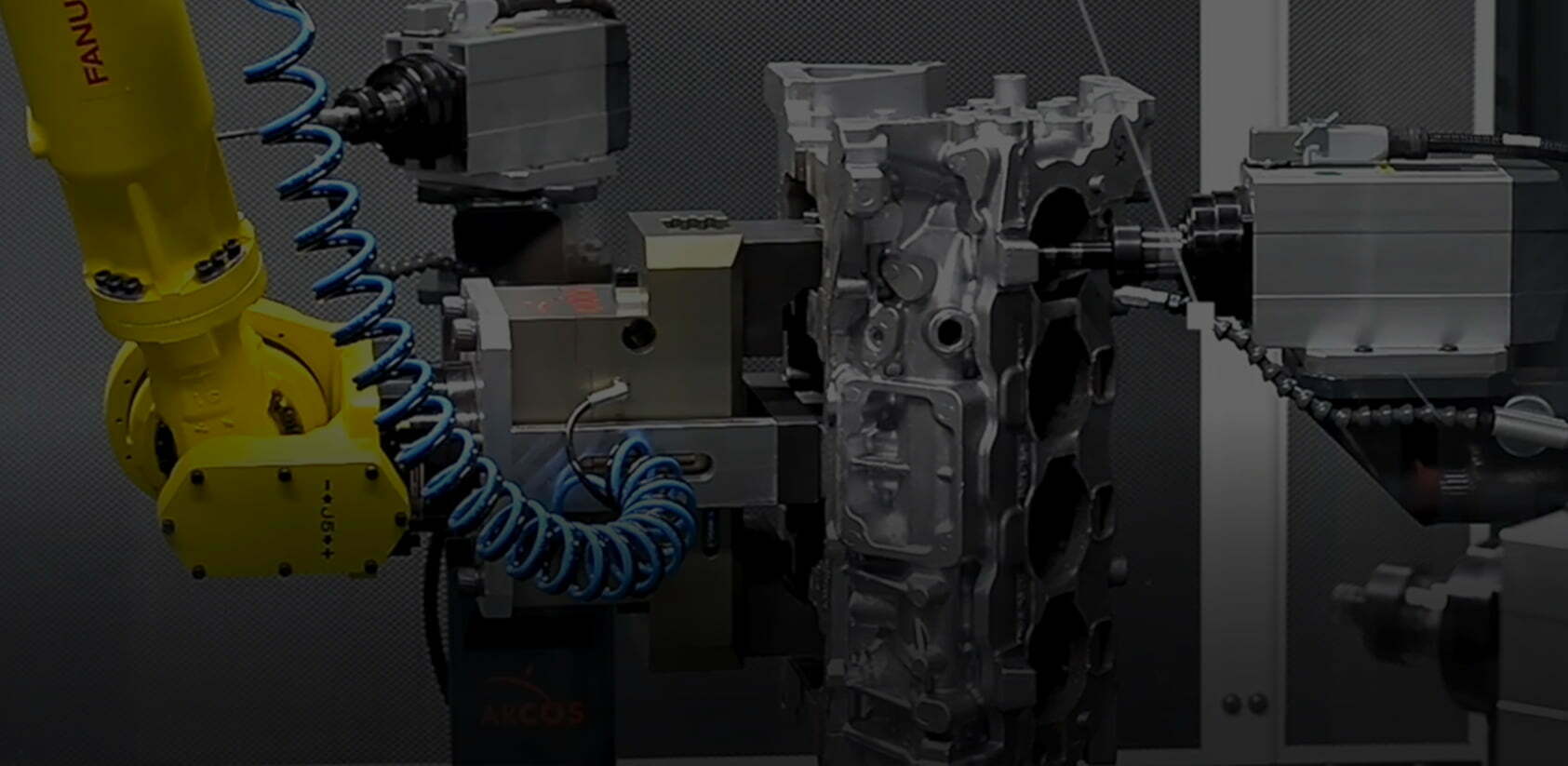

Automated robotic deburring machine

Flawless finishing and consistent quality

Maximize cost savings

STUDY CASES FOR DEBURRING

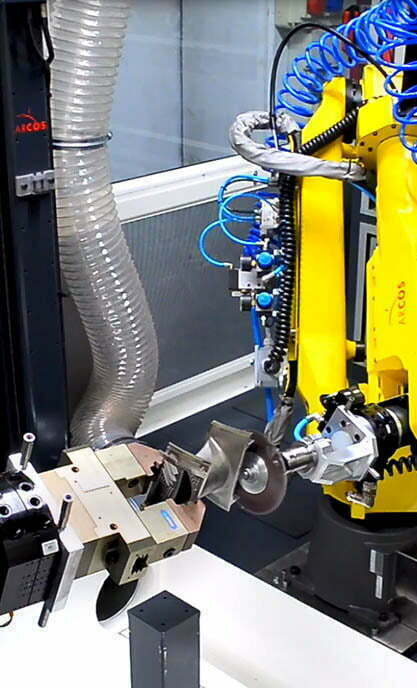

Aerospace: Precision deburring of turbine blades

The robotic system automatically removes burrs, starting from blades for micro-fused turbine that have different torsions.

The robotic system allows to remove the burrs resulting from the installation process of the cores with hinge inside the temples. The deburring of the hinge seat takes place automatically thanks to the application of a sophisticated vision system that, with the use of three cameras, allows to identify at each operation the positioning of the burrs to be removed. Then the robotic system proceeds with the cutting program for the removal of burrs..

Recommended machines for deburring

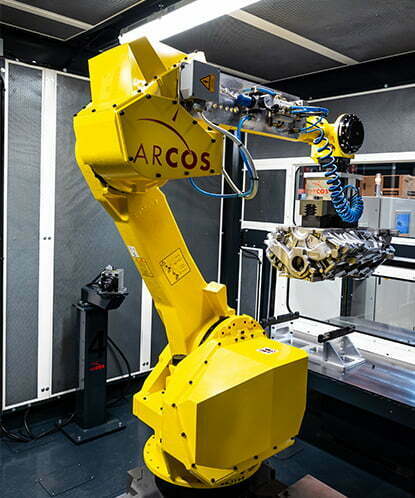

ROBOTISED SYSTEMS

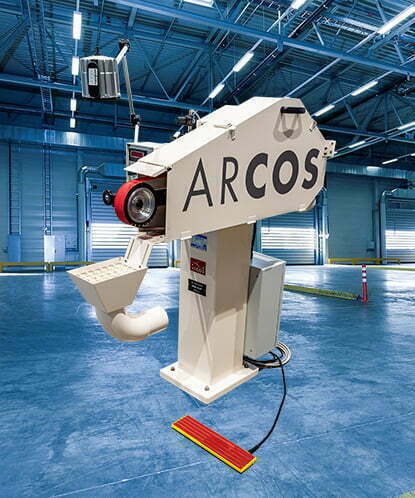

MANUAL MACHINES

DEBURRING

type of materials

cast iron

glass

aluminum alloys

Steel/stainless steel

brass

Zamak

hard stones

titanium alloys

Inconel ®

magnesium alloys

composite materials

Plastic