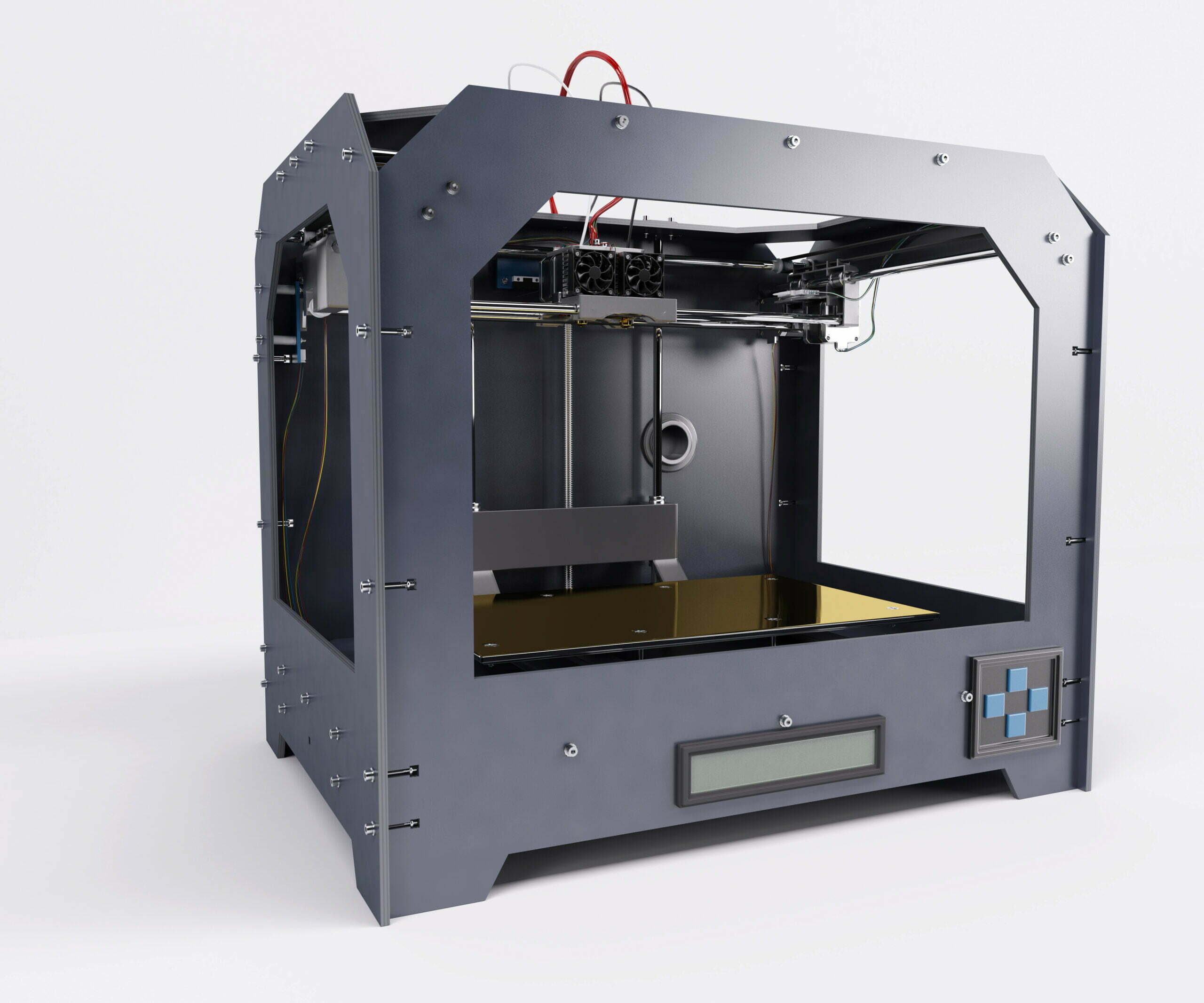

Additive printers are a growing phenomenon in the world of manufacturing. These tools lend themselves to a variety of useful functions for companies, enabling the creation of objects from 3D digital models.

Let’s take a look at the advantages of 3D printing, and how Arcos has integrated it into its own reality, in the service of its customers’ growth.

Table of Contents

WHAT IS 3D PRINTING?

3D printing is a type of additive manufacturing: it creates three-dimensional objects using a digital 3D model as a reference. The printer uses the model supplied by a computer to create a series of cross-sectional portions: each portion is printed one after the other until the final 3D object is obtained. This is why it’s called additive manufacturing: the object is machined by adding material, rather than removing it, as is the case with milling or turning, and is therefore defined as subtractive production.

THE ADVANTAGES OF 3D PRINTING

The advantages of 3D printers are many: firstly, they are faster, safer and easier to use than other technologies, and enable considerable material savings in product realization. With a single construction process, they guarantee the printing and assembly of parts in different materials, even those characterized by different physical and mechanical properties. What’s more, they improve object performance by enabling the creation of very light molds without sacrificing any of the element’s mechanical properties.

But that’s not all: with 3D printing, production times and costs are considerably reduced. In fact, the model is produced in a matter of hours, and whereas previously you had to wait days or weeks to see a prototype, with this technology you can get rapid confirmation of the result.

Labor costs are extremely limited, as only one qualified person is needed to start printing, while the energy costs of the machine, which turns out to be the same as a laptop, are optimized by the ability to produce in a single phase. The cost of the material, whether a coil of filament or resin, is lightened by the savings in quantity over traditional processes.

Finally, with the 3D printer, there’s no complexity involved in making an object. So there are no limits to creativity or customization: to modify an object, all you have to do is apply the desired changes to the 3D model, without any concrete constraints or difficulties.

3D PRINTING ENTERS THE WORLD OF ARCOS

Thanks to the possibility of daily visits to clients from very different sectors, Arcos has been able to observe the significant evolution of 3D printing in the manufacturing world within everyday professional life. It is precisely for this reason that a 3D printer has been introduced into their fleet, capable of meeting the increasingly specific needs of clients and allowing them to take advantage of this technology.

3D printing has been integrated into Arcos’ robotic reality in two ways:

- To design and manufacture tooling components such as robot grippers, positions of rotary tables on which parts are placed to be machined, indexing stations, or part flipping stations (when it is necessary to load the cell). All these elements change depending on the product, hence the usefulness of 3D printing: they can be custom-designed and seamlessly integrated into the Arcos cell.

- When it is necessary to process the products from printing, whether by grinding, polishing, or otherwise.

FOR EVERY NEED, THERE’S A SOLUTION: THE EXAMPLE OF THE ARCOS CUSTOMER

The idea of introducing a 3D printer arose during a visit to an Arcos customer, where changes were noted in relation to the system initially installed. The positions, claws and reference elements of the parts were different from those installed during the test phase. How was this possible?

The customer, faced with different types of orders, different products and variable production batches, and not wanting to give up the convenience of Arcos cells for a return to manual work, decided to produce these parts in-house using a 3D printer. In this way, he not only educed tooling costs, but was also able to guarantee the production of these components, freeing himself from the limitations imposed by constantly changing orders.

By reducing lead times and broadening the range of products that could be produced, he customer was able to benefit both economically and logistically. In fact, as we no longer had to ask third parties to produce these elements, there were no longer any problems associated with delays or imperfections. Witnessing this successful example, Arcos wanted to exploit this product to make the cell manufacturing process faster and even more precise than before.

THE EVOLUTION OF THIS TECHNOLOGY AND THE FUTURE OF THE SECTORS

Additive manufacturing has seen a rapid evolution in various sectors and is used in many fields: from the production of medical prostheses to the manufacturing of aerospace components, as well as its use in the automotive field and even in the costume jewelry sector. These are production methods that one must start to familiarize oneself with: the materials, geometries, and fragilities represent a new challenge, a source of stimulation and enthusiasm for the Arcos world.

The 3D printer is therefore not only considered as a tool for integration to speed up and perfect robotic cells, but it is also the result of a production process with which Arcos will interface for future surface treatments. In the future, there will be fewer forged parts, cast parts, or mechanical processes and more details made with additives: developing a 360-degree knowledge of the sector, its critical issues, and strengths thus becomes essential to ensure the best possible service to the client.

CONCLUSION

3D printing is a technology that is becoming part of multiple realities in the manufacturing sector. Indeed, this type of additive manufacturing offers numerous advantages: speed, precision, material and cost savings, and great creative freedom. For this reason, Arcos has also decided to integrate a 3D printer into its own operations to optimize processing and always ensure the best for its clients.

Do you want more information on this topic? Contact us: our team is at your disposal to answer all your questions.